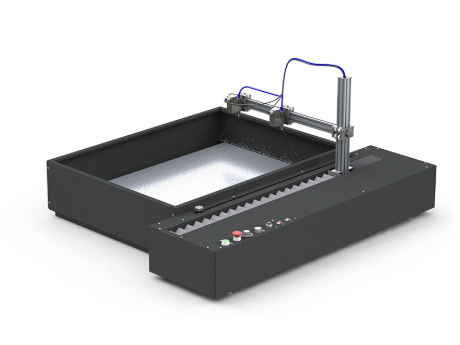

DTG printer: Open Spray Machine

Product Description

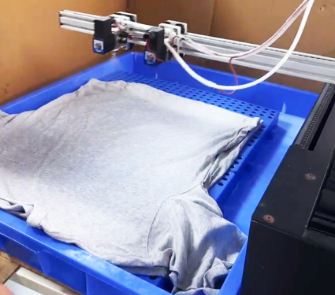

A pretreatment tool made specifically for DTG printing is the Open Spray Pretreatment Machine. Before printing, it is mostly used to evenly spray pretreatment solutions onto textiles (such cotton, polyester, or hybrid materials). The purpose of the pretreatment liquid is to maximise the fabric's surface area for improved ink adhesion, which enhances colour vibrancy, washability, and print quality overall.

The open spray machine employs an automated spraying system to guarantee that every article of clothing can be uniformly coated with pretreatment liquid, minimising human error and enhancing production uniformity as compared to conventional immersion or manual spraying techniques.

The open spray machine employs an automated spraying system to guarantee that every article of clothing can be uniformly coated with pretreatment liquid, minimising human error and enhancing production uniformity as compared to conventional immersion or manual spraying techniques.

Product advantages

-

Boost colour performance and printing quality.

-

Lower labour expenses and increase production efficiency.

-

Lower expenses and preserve pretreatment liquid.

- Suitable for DTG printers and a range of textiles.

-

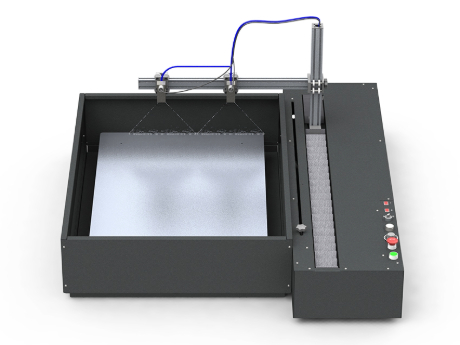

Use stainless steel nozzles for long-term stable functioning because they are resistant to corrosion and difficult to clog. To prevent leaks, the multi-nozzle design covers every area of the garment.

Use stainless steel nozzles for long-term stable functioning because they are resistant to corrosion and difficult to clog. To prevent leaks, the multi-nozzle design covers every area of the garment. -

To cut down on waste, an integrated circulation system can recycle extra pretreatment liquid. Low energy consumption and noise levels are consistent with the environmental protection standards of contemporary factories.

To cut down on waste, an integrated circulation system can recycle extra pretreatment liquid. Low energy consumption and noise levels are consistent with the environmental protection standards of contemporary factories. -

To avoid blockage, the nozzle can be dismantled and cleaned. Cleaning and troubleshooting are made easier by the open architecture.

To avoid blockage, the nozzle can be dismantled and cleaned. Cleaning and troubleshooting are made easier by the open architecture. -

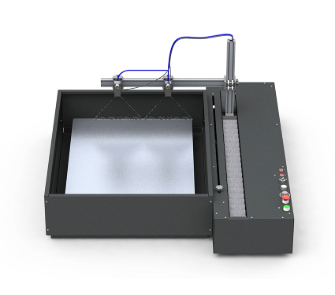

The spray speed, spray volume, and operating mode can all be changed using the touch screen operation panel. supports one-click switching between various process requirements and sets several fabric treatment solutions.

The spray speed, spray volume, and operating mode can all be changed using the touch screen operation panel. supports one-click switching between various process requirements and sets several fabric treatment solutions.