Is A UV Printer Permanent?

Durability is a major consideration when spending money on custom printing for goods, packaging, or industrial components. "Is UV printing permanent?" is a question that many firms have.

This article will cover the following topics:

✔ What permanent UV printing is

✔ What influences the longevity of UV prints

✔ How UV printing differs from other techniques

✔ How to extend print lifespan

You'll be able to decide before placing your order if UV printing is the best option for your project by the end.

Typical Applications for UV Printing:

promotional items (phone cases, pens, and mugs)

Machinery parts and industrial labelling

Retail displays and packaging

Outdoor advertising and signage

1. Surface of the Material

Ideal for: Non-porous, hard surfaces (acrylic, metal, glass, and plastic)

Flexible or textured materials (such as textiles or untreated wood) are less resilient.

2. The Curing Process of Ink

Under UV light, UV ink instantly hardens and forms a solid bond.

Maximum adhesion and scratch resistance are guaranteed by proper curing.

3. Environmental Aspects

Sunlight (UV exposure): Over time, fade may result from prolonged exposure to direct sunlight.

Chemicals and abrasion: May break down when exposed to strong solvents, yet resistant to gentle cleaning.

Indoor versus outdoor use: Compared to 2–3 years outside, UV prints last longer indoors (5+ years).

4. Treatments After Printing

The longevity can be increased by applying a protective varnish or laminate.

Steer clear of rough cloths and steel wool, which are abrasive cleaning supplies.

Ideal For: Detailed printing and hard surfaces

Duration of life: 2–5+ years

Key Benefit: Vibrant colours on a variety of surfaces and instant curing

2. Durability of Pad Printing: Moderate (wears with friction)

Ideal For: Tiny logos on curved surfaces

Duration: 1–3 years

Principal Benefit: economical for small quantities of irregularly shaped

3. Durability of Screen Printing: Good (thick ink layers)

Ideal For: Bulk orders, posters, and fabric

Duration: 1–4 years

Main Benefit: Cost-effective for big quantities

4. Sublimation of Dye

Permanent durability (for polyester materials)

Ideal For: Soft Signage, Clothing

Lifespan: more than five years

The main benefit is that full-color, seamless textile prints

5. Engraving using a laser

Permanent durability (etched into the substance)

Ideal For: Industrial parts, wood, and metal

Duration: Infinite

Key Benefit: Exceptionally robust and ink-free

A Brief Synopsis of the Comparison

The most resilient include dye sublimation, laser engraving, and UV printing.

UV printing is the most versatile method; it can be used on most materials.

Ideal for Textiles: Sublimation of dyes

Pad printing works well for small batches.

Screen printing works best for large orders.

✔ Apply a protective layer (for increased scratch resistance, choose a glossy or matte laminate).

✔ Steer clear of harsh chemicals and clean with water and gentle soap.

✔ For outdoor use, opt for UV-resistant inks & laminates.

Ideal for: ✅ Superior branding on hard surfaces ✅ Product labels and packaging that are resistant to scratches

✅ Temporary to intermediate outdoor signage (with coatings for protection)

Unsuitable for: ❌ Severe outdoor circumstances (five years or more of direct sunshine) ❌ Fabric and other flexible materials

Does your company require long-lasting UV printing? For a free quote, contact us right now!

This article will cover the following topics:

✔ What permanent UV printing is

✔ What influences the longevity of UV prints

✔ How UV printing differs from other techniques

✔ How to extend print lifespan

You'll be able to decide before placing your order if UV printing is the best option for your project by the end.

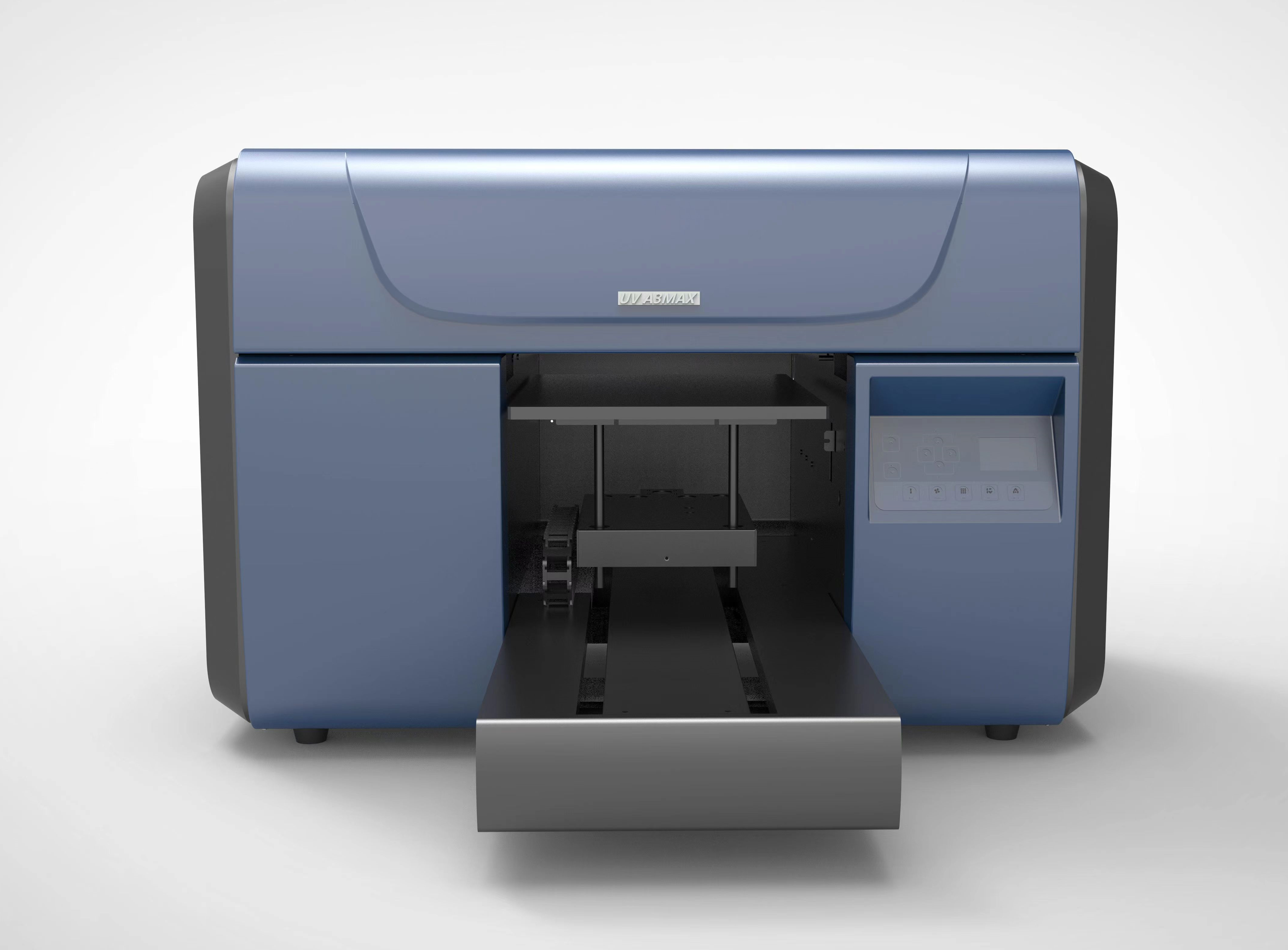

How Does UV Printing Work?

UV printing applies ink to a surface and employs ultraviolet (UV) light to cure it instantly. UV printing immediately fuses the ink to the substrate, producing a durable, scratch-resistant finish, in contrast to traditional printing, which depends on heat or air drying.Typical Applications for UV Printing:

promotional items (phone cases, pens, and mugs)

Machinery parts and industrial labelling

Retail displays and packaging

Outdoor advertising and signage

Does UV Printing Last?

Although UV prints survive a long time, they are not entirely permanent. What influences their durability is as follows:1. Surface of the Material

Ideal for: Non-porous, hard surfaces (acrylic, metal, glass, and plastic)

Flexible or textured materials (such as textiles or untreated wood) are less resilient.

2. The Curing Process of Ink

Under UV light, UV ink instantly hardens and forms a solid bond.

Maximum adhesion and scratch resistance are guaranteed by proper curing.

3. Environmental Aspects

Sunlight (UV exposure): Over time, fade may result from prolonged exposure to direct sunlight.

Chemicals and abrasion: May break down when exposed to strong solvents, yet resistant to gentle cleaning.

Indoor versus outdoor use: Compared to 2–3 years outside, UV prints last longer indoors (5+ years).

4. Treatments After Printing

The longevity can be increased by applying a protective varnish or laminate.

Steer clear of rough cloths and steel wool, which are abrasive cleaning supplies.

Important Differences Between UV Printing and Other Printing Techniques

1. UV Printing Durability: Excellent resistance to water and scratchesIdeal For: Detailed printing and hard surfaces

Duration of life: 2–5+ years

Key Benefit: Vibrant colours on a variety of surfaces and instant curing

2. Durability of Pad Printing: Moderate (wears with friction)

Ideal For: Tiny logos on curved surfaces

Duration: 1–3 years

Principal Benefit: economical for small quantities of irregularly shaped

3. Durability of Screen Printing: Good (thick ink layers)

Ideal For: Bulk orders, posters, and fabric

Duration: 1–4 years

Main Benefit: Cost-effective for big quantities

4. Sublimation of Dye

Permanent durability (for polyester materials)

Ideal For: Soft Signage, Clothing

Lifespan: more than five years

The main benefit is that full-color, seamless textile prints

5. Engraving using a laser

Permanent durability (etched into the substance)

Ideal For: Industrial parts, wood, and metal

Duration: Infinite

Key Benefit: Exceptionally robust and ink-free

A Brief Synopsis of the Comparison

The most resilient include dye sublimation, laser engraving, and UV printing.

UV printing is the most versatile method; it can be used on most materials.

Ideal for Textiles: Sublimation of dyes

Pad printing works well for small batches.

Screen printing works best for large orders.

How to Extend the Life of UV Prints

Select the appropriate material (smooth, non-porous surfaces work best) to optimise durability.✔ Apply a protective layer (for increased scratch resistance, choose a glossy or matte laminate).

✔ Steer clear of harsh chemicals and clean with water and gentle soap.

✔ For outdoor use, opt for UV-resistant inks & laminates.

In summary, is UV printing a good fit for you?

For the majority of commercial, promotional, and retail applications, UV printing is an incredibly robust and long-lasting option. Although not entirely permanent, it performs better in terms of colour vibrancy and scratch resistance than many conventional printing techniques.Ideal for: ✅ Superior branding on hard surfaces ✅ Product labels and packaging that are resistant to scratches

✅ Temporary to intermediate outdoor signage (with coatings for protection)

Unsuitable for: ❌ Severe outdoor circumstances (five years or more of direct sunshine) ❌ Fabric and other flexible materials

Does your company require long-lasting UV printing? For a free quote, contact us right now!

RECENT POSTS

-

Is UV Print Better Than Eco Print? A Comprehensive Comparison for B2B Buyers

-

Is UV Printing Better Than Pad Printing?

-

Ist UV-Druck besser als Öko-Druck? Ein umfassender Vergleich für B2B-Käufer

-

Is A UV Printer Permanent?

-

Open spray machine: the perfect supporting equipment to improve the efficiency of DTG industrial printers

Application

-

UV DTF printer for Gold silver stickersGold and silver stickers that many customers like, let's see how it is made.

UV DTF printer for Gold silver stickersGold and silver stickers that many customers like, let's see how it is made. -

Vango DTF printerOur DTF printer adopts an all-in-one printing design, which is more space-saving and easier to operate.This is our printing show.

Vango DTF printerOur DTF printer adopts an all-in-one printing design, which is more space-saving and easier to operate.This is our printing show.

Wide applications,design for textile printing,Suitable for all kinds of fabrics, T-shirts,leather, bags and shoes etc.

More Application