How to Fix Banding on Large Format Prints: A Complete Troubleshooting Guide

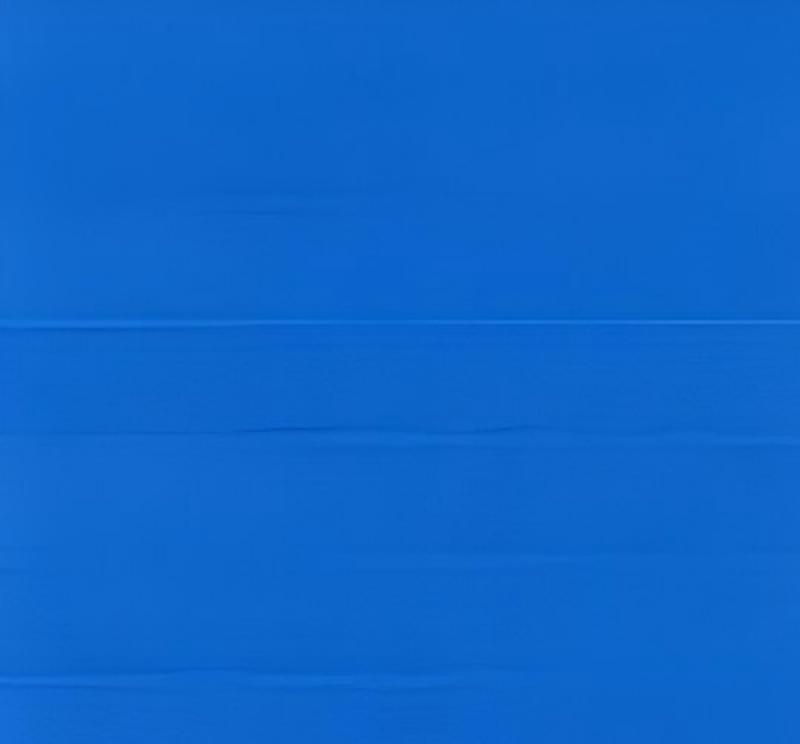

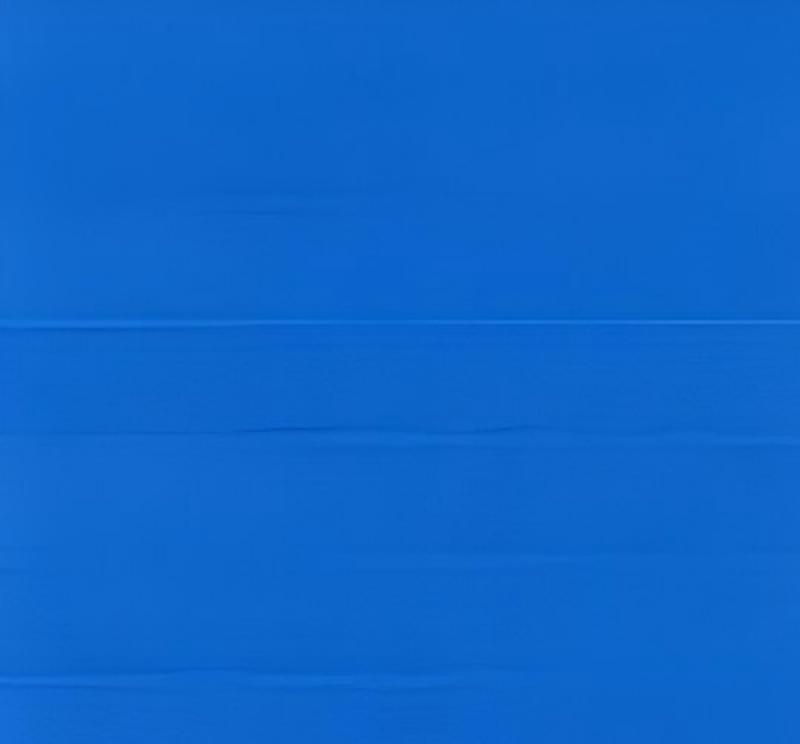

One of the most prevalent quality problems in big format printing is banding, which are those annoying vertical or horizontal lines that show up in your prints. Banding can detract from an otherwise flawless print project, whether you're creating banners, car wraps, trade fair posters, or architectural drawings. Everything you need to know about spotting, resolving, and avoiding banding problems in your big format prints will be covered in this thorough book.

Visible lines or streaks that show up in printed output and usually run either vertically or horizontally across the print are referred to as banding. These lines show regions of the media where ink has not been applied correctly, resulting in pronounced differences in colour density.

Banding Types

Lines parallel to the printhead movement are known as horizontal banding.

Vertical banding: Lines that are perpendicular to the movement of the printhead

Random Banding: Unpredictable patterns of irregular stripes

The Impact of Banding on Print Quality

lessens detail and sharpness.

produces asymmetrical colour changes.

causes slopes to look stepped rather than smooth.

makes prints seem less than professional.

Some prints may become unusable for client work.

Printers that are not frequently used

Low-humidity environments

Some types of ink that dry more quickly

Not aligned Printheads: A little misalignment can result in:

Intervals between printhead runs

Darker lines are produced by overlapping.

seams that are visible in the printed output

Exhausted Printheads: Earlier printheads could:

behave inconsistently as a nozzle

Create anomalies in firing

Display poor ink droplet control

Poor performance of the nozzle

Clogging problems

Uneven drying properties

The wrong ink Viscosity causes issues with droplet formation.

Unreliable dot positioning

Ink laydown is poor.

Expired ink could: Change in chemical composition

Hold particles that clog nozzles in check.

Not meeting the requirements

Inadequate absorption of ink

Pooling or beading

Inequitable dot gain

Poor media frequently has:

Surface treatments that are inconsistent

Differential porosity

Inadequate coatings

Inappropriate media handling, such as surface dust or debris

Oils or fingerprints

Problems with static electricity

Strips that are not correctly tensioned

Problems with strip alignment

Problems with the Carriage Mechanism: Damaged bushings or bearings

Belts that are loose

Unaligned rails

Issues with Media Advancement:

Pinch rollers that are worn

Feed mechanisms that slip

Unreliable media movement

5. Environmental Elements

Variations in temperature have an impact on ink viscosity.

Dimensions of the media

Tolerances in mechanics

Impact of Humidity Variations: Ink drying times

Moisture content of media

accumulation of static electricity

Printhead clogging can be caused by dust and contaminants.

interfere with the mechanical components

Media surfaces that are contaminated

To find clogged nozzles, use the printer's integrated nozzle check.

Go through the printer's settings and run a printhead cleaning cycle.

For difficult clogs, manually wipe the printhead with a lint-free cloth and cleaning solution.

2. Make Use of Superior Ink and Media

Always use the ink that the manufacturer recommends because inks from other companies could not dry well.

Select premium media made for the model of your printer.

To avoid drying out, keep medium and ink in a temperature-controlled environment.

3. Modify the Print Preferences

Use "High Quality" or "Fine" mode rather than "Draft" to increase the print resolution.

Reduce banding by turning off "High-Speed" printing.

In the printer's options, choose the appropriate media type (such as "Glossy Paper" or "Vinyl").

4. Adjust and Adjust Printheads

Use the printer's settings to activate the automatic printhead alignment function.

Perform manual calibration (follow the instructions in your printer handbook) if problems continue.

5. Examine the printer's mechanics

Check for wear and tear on motors, belts and rollers.

To prevent movement mistakes, make sure the printer is on a level, sturdy surface.

If necessary, lubricate moving parts (see the manufacturer's instructions).

✅ Use Original Ink: Steer clear of inexpensive alternatives that clog nozzles.

✅ Properly Store Media: Store rolls in desiccants in sealed bags.

✅ Arrange for Professional Servicing: Printer life is increased by yearly maintenance.

Are You Still Seeing Banding? Seek Expert Assistance!

After troubleshooting, if banding still occurs, your printer might require expert repair or part replacement.

Hstar specialises in big format printing solutions, including high-quality prints and equipment maintenance.

For professional assistance, contact us right now!

Section 1: What is banding exactly?

Using Printing Terms to Define BandingVisible lines or streaks that show up in printed output and usually run either vertically or horizontally across the print are referred to as banding. These lines show regions of the media where ink has not been applied correctly, resulting in pronounced differences in colour density.

Banding Types

Lines parallel to the printhead movement are known as horizontal banding.

Vertical banding: Lines that are perpendicular to the movement of the printhead

Random Banding: Unpredictable patterns of irregular stripes

The Impact of Banding on Print Quality

lessens detail and sharpness.

produces asymmetrical colour changes.

causes slopes to look stepped rather than smooth.

makes prints seem less than professional.

Some prints may become unusable for client work.

Section 2: The Fundamental Reasons for Banding

The first step in preventing banding is to understand what causes it. Here is a detailed list of the main offenders:1. Problems with the printhead (most frequent cause)

Clogged Nozzles: Proper ink flow is blocked when ink dries in the nozzles. This is particularly prevalent with:Printers that are not frequently used

Low-humidity environments

Some types of ink that dry more quickly

Not aligned Printheads: A little misalignment can result in:

Intervals between printhead runs

Darker lines are produced by overlapping.

seams that are visible in the printed output

Exhausted Printheads: Earlier printheads could:

behave inconsistently as a nozzle

Create anomalies in firing

Display poor ink droplet control

2. Issues Concerning Ink

Poor ink quality can result in:Poor performance of the nozzle

Clogging problems

Uneven drying properties

The wrong ink Viscosity causes issues with droplet formation.

Unreliable dot positioning

Ink laydown is poor.

Expired ink could: Change in chemical composition

Hold particles that clog nozzles in check.

Not meeting the requirements

3. Issues with the Media

Media incompatibilities may result in:Inadequate absorption of ink

Pooling or beading

Inequitable dot gain

Poor media frequently has:

Surface treatments that are inconsistent

Differential porosity

Inadequate coatings

Inappropriate media handling, such as surface dust or debris

Oils or fingerprints

Problems with static electricity

4. Mechanical Problems

Issues with Encoder Strips: Unclean or broken encoder stripsStrips that are not correctly tensioned

Problems with strip alignment

Problems with the Carriage Mechanism: Damaged bushings or bearings

Belts that are loose

Unaligned rails

Issues with Media Advancement:

Pinch rollers that are worn

Feed mechanisms that slip

Unreliable media movement

5. Environmental Elements

Variations in temperature have an impact on ink viscosity.

Dimensions of the media

Tolerances in mechanics

Impact of Humidity Variations: Ink drying times

Moisture content of media

accumulation of static electricity

Printhead clogging can be caused by dust and contaminants.

interfere with the mechanical components

Media surfaces that are contaminated

How to Correct Banding: Detailed Instructions

1. Make the printheads clean.To find clogged nozzles, use the printer's integrated nozzle check.

Go through the printer's settings and run a printhead cleaning cycle.

For difficult clogs, manually wipe the printhead with a lint-free cloth and cleaning solution.

2. Make Use of Superior Ink and Media

Always use the ink that the manufacturer recommends because inks from other companies could not dry well.

Select premium media made for the model of your printer.

To avoid drying out, keep medium and ink in a temperature-controlled environment.

3. Modify the Print Preferences

Use "High Quality" or "Fine" mode rather than "Draft" to increase the print resolution.

Reduce banding by turning off "High-Speed" printing.

In the printer's options, choose the appropriate media type (such as "Glossy Paper" or "Vinyl").

4. Adjust and Adjust Printheads

Use the printer's settings to activate the automatic printhead alignment function.

Perform manual calibration (follow the instructions in your printer handbook) if problems continue.

5. Examine the printer's mechanics

Check for wear and tear on motors, belts and rollers.

To prevent movement mistakes, make sure the printer is on a level, sturdy surface.

If necessary, lubricate moving parts (see the manufacturer's instructions).

Tips for Preventive Maintenance to Prevent Banding

✅ Print Often: Weekly printer runs keep ink from drying out.✅ Use Original Ink: Steer clear of inexpensive alternatives that clog nozzles.

✅ Properly Store Media: Store rolls in desiccants in sealed bags.

✅ Arrange for Professional Servicing: Printer life is increased by yearly maintenance.

Are You Still Seeing Banding? Seek Expert Assistance!

After troubleshooting, if banding still occurs, your printer might require expert repair or part replacement.

Hstar specialises in big format printing solutions, including high-quality prints and equipment maintenance.

For professional assistance, contact us right now!

RECENT POSTS

-

How to Fix Banding on Large Format Prints: A Complete Troubleshooting Guide

-

What Is The Difference Between Standard Print And Large Print?

-

How to Calibrate Industrial Printer Color Accuracy?

-

What Is The Difference Between Industrial And Consumer 3d Printers?

-

ما هما النوعان الرئيسيان للطابعات ثلاثية الأبعاد؟

Application

-

Application scenarios of UV DTF printersUV DTF printer is our NEW machine, which is loved by many consumers.crystal stickers are widely used.

Application scenarios of UV DTF printersUV DTF printer is our NEW machine, which is loved by many consumers.crystal stickers are widely used.

Crystal stickers can also be used as decorations to make your gift more beautiful and special. -

UV DTF printer for Gold silver stickersGold and silver stickers that many customers like, let's see how it is made.

UV DTF printer for Gold silver stickersGold and silver stickers that many customers like, let's see how it is made.

More Application