What Is The Difference Between Industrial And Consumer 3d Printers?

Rapid advancements in 3D printing technology have produced solutions for both individual and commercial users. But not every 3D printer is created equal. Performance, materials, cost, and applications are the main areas where industrial and consumer (desktop) 3D printers diverge.

designed for demanding, ongoing use in manufacturing settings, such as factories.

crafted with precision parts and premium metal frames for enduring dependability.

made to require little maintenance and operate around the clock.

3D printers for consumers

Usually constructed with lightweight metal frames or plastic to save money.

Ideal for sporadic use (a few hours per day).

More regular calibration and part replacements might be necessary.

In conclusion, consumer printers are better suited for small-scale projects or hobbyists, whereas industrial printers are made to last.

Provide precision products with tighter tolerances (up to ±0.1mm or greater).

able to manage huge prints without sacrificing quality.

3D printers for consumers

reduced print rates to avoid expenses and noise.

Accuracy is typically between ±0.2 and ±0.5 mm, which is good for prototypes but not always for final components.

reduced build volumes, often less than 300 x 300 x 300 mm.

In conclusion, consumer printers are slower but adequate for basic needs, whereas industrial printers generate faster, more accurate prints.

able to print using materials of engineering quality such as

Polycarbonate (PC), nylon, ABS, PEEK, and ULTEM (high heat resistance)

Metal powders (SLS/DMLS) for use in medicine and aircraft

Composites and resins that resemble rubber

frequently has heated beds and covered spaces to stop warping.

3D printers for consumers

mostly restricted to TPU, PETG, PLA, and simple ABS.

Carbon-fibre or nylon filaments are not supported by several models.

High-temperature materials can cause warping in open-frame designs.

In summary, consumer printers are best suited for basic plastics and prototyping, whereas industrial printers can handle stronger, more lasting materials.

increased operational expenses (maintenance, energy use, specialised materials).

Designed for the automotive, aerospace, medical, and mass manufacturing sectors.

From entry-level to prosumer models, consumer 3D printers range from 200 to 3,000.

low cost of filament (PLA and PETG are reasonably priced).

Perfect for small enterprises, educators, and hobbyists.

Conclusion: While consumer printers are reasonably priced for individual use, industrial printers require a significant investment from businesses.

✔ Functional prototypes (stress-tested parts)

End-use production components (aerospace, automotive)

✔ Custom prostheses and medical implants

✏ Manufacturing aids and tools

Consumer 3D Printers Are Used For:

Custom toys, figurines, and home décor; educational models and school projects; hobby projects and do-it-yourself crafts; and small-scale prototyping are among applications for consumer 3D printers.

✅ High accuracy and consistency

✅ Robust, heat-resistant materials

✅ Continuous or large-scale manufacturing

✅ Adherence to industry standards (FDA, ISO, etc.)

Consider purchasing a consumer 3D printer if you require:

✅ Low-cost hobby printing and prototyping

✅ Plug-and-play, user-friendly operation

✅ Small to medium-sized prints

✅ Simple material options (PLA, PETG, TPU)

For dependability and performance, manufacturers and businesses should invest in industrial-grade machinery.

For entrepreneurs, schools, and hobbyists, consumer 3D printers will be more than adequate.

Get in touch with our professionals for a free consultation if you're still not sure which kind is best for you!

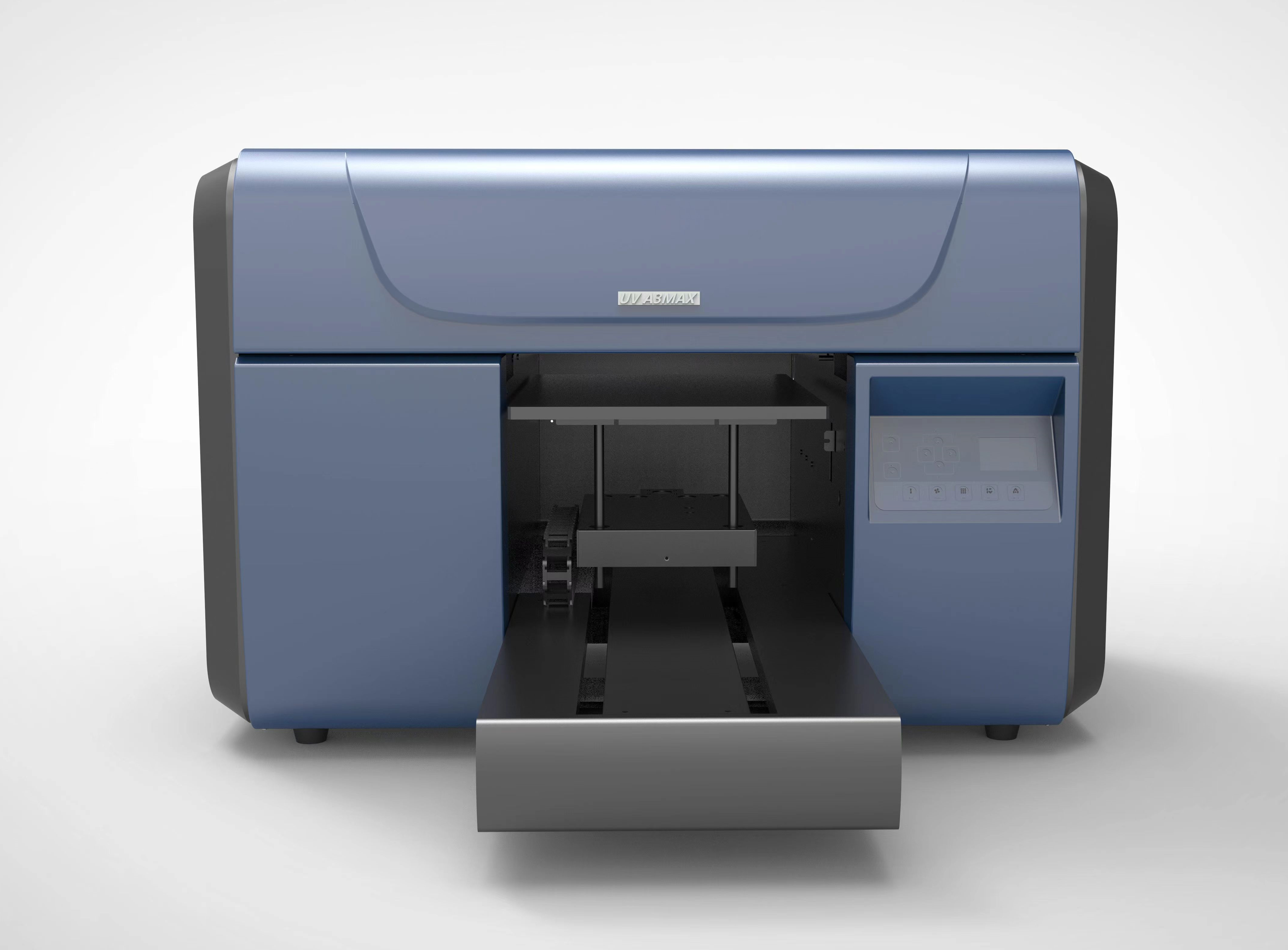

Are You Curious About Industrial 3D Printers?

�� For a quote, contact us right now!

1. Construction Quality and Sturdiness

3D printers for industrydesigned for demanding, ongoing use in manufacturing settings, such as factories.

crafted with precision parts and premium metal frames for enduring dependability.

made to require little maintenance and operate around the clock.

3D printers for consumers

Usually constructed with lightweight metal frames or plastic to save money.

Ideal for sporadic use (a few hours per day).

More regular calibration and part replacements might be necessary.

In conclusion, consumer printers are better suited for small-scale projects or hobbyists, whereas industrial printers are made to last.

2. Accuracy & Print Speed of Industrial 3D Printers

significantly quicker because to high-power motors and sophisticated extrusion technologies.Provide precision products with tighter tolerances (up to ±0.1mm or greater).

able to manage huge prints without sacrificing quality.

3D printers for consumers

reduced print rates to avoid expenses and noise.

Accuracy is typically between ±0.2 and ±0.5 mm, which is good for prototypes but not always for final components.

reduced build volumes, often less than 300 x 300 x 300 mm.

In conclusion, consumer printers are slower but adequate for basic needs, whereas industrial printers generate faster, more accurate prints.

3. Compatibility of Materials

3D printers for industryable to print using materials of engineering quality such as

Polycarbonate (PC), nylon, ABS, PEEK, and ULTEM (high heat resistance)

Metal powders (SLS/DMLS) for use in medicine and aircraft

Composites and resins that resemble rubber

frequently has heated beds and covered spaces to stop warping.

3D printers for consumers

mostly restricted to TPU, PETG, PLA, and simple ABS.

Carbon-fibre or nylon filaments are not supported by several models.

High-temperature materials can cause warping in open-frame designs.

In summary, consumer printers are best suited for basic plastics and prototyping, whereas industrial printers can handle stronger, more lasting materials.

4. Cost Comparison

Depending on the technology (FDM, SLS, SLA, DMLS), industrial 3D printers range in price from 10,000 to 500,000+.increased operational expenses (maintenance, energy use, specialised materials).

Designed for the automotive, aerospace, medical, and mass manufacturing sectors.

From entry-level to prosumer models, consumer 3D printers range from 200 to 3,000.

low cost of filament (PLA and PETG are reasonably priced).

Perfect for small enterprises, educators, and hobbyists.

Conclusion: While consumer printers are reasonably priced for individual use, industrial printers require a significant investment from businesses.

5. Use Cases & Applications

The following applications for industrial 3D printers exist:✔ Functional prototypes (stress-tested parts)

End-use production components (aerospace, automotive)

✔ Custom prostheses and medical implants

✏ Manufacturing aids and tools

Consumer 3D Printers Are Used For:

Custom toys, figurines, and home décor; educational models and school projects; hobby projects and do-it-yourself crafts; and small-scale prototyping are among applications for consumer 3D printers.

What Should You Pick?

Invest in an industrial 3D printer if you require:✅ High accuracy and consistency

✅ Robust, heat-resistant materials

✅ Continuous or large-scale manufacturing

✅ Adherence to industry standards (FDA, ISO, etc.)

Consider purchasing a consumer 3D printer if you require:

✅ Low-cost hobby printing and prototyping

✅ Plug-and-play, user-friendly operation

✅ Small to medium-sized prints

✅ Simple material options (PLA, PETG, TPU)

Concluding remarks

Your budget, material requirements, and production size will all influence your decision between industrial and consumer 3D printers.For dependability and performance, manufacturers and businesses should invest in industrial-grade machinery.

For entrepreneurs, schools, and hobbyists, consumer 3D printers will be more than adequate.

Get in touch with our professionals for a free consultation if you're still not sure which kind is best for you!

Are You Curious About Industrial 3D Printers?

�� For a quote, contact us right now!

RECENT POSTS

-

What Is The Difference Between Industrial And Consumer 3d Printers?

-

ما هما النوعان الرئيسيان للطابعات ثلاثية الأبعاد؟

-

ما هو الفرق بين الطابعات ثلاثية الأبعاد الصناعية والاستهلاكية؟

-

Which Type of Printer Is Best for High-Volume Document Printing?

-

How Long Do Industrial Printers Last? A Practical Guide for Businesses

Application

-

DTF Printer Effect ShowDirect to film printer(DTF printers) are T-shirt transfer printers,Hstar DTF printer offer a transfer solution especially for dark color fabric,which is a creative application process.

DTF Printer Effect ShowDirect to film printer(DTF printers) are T-shirt transfer printers,Hstar DTF printer offer a transfer solution especially for dark color fabric,which is a creative application process. -

Application scenarios of UV DTF printersUV DTF printer is our NEW machine, which is loved by many consumers.crystal stickers are widely used.

Application scenarios of UV DTF printersUV DTF printer is our NEW machine, which is loved by many consumers.crystal stickers are widely used.

Crystal stickers can also be used as decorations to make your gift more beautiful and special.

More Application