How to Inspect Newly Delivered Industrial Printing Equipment?

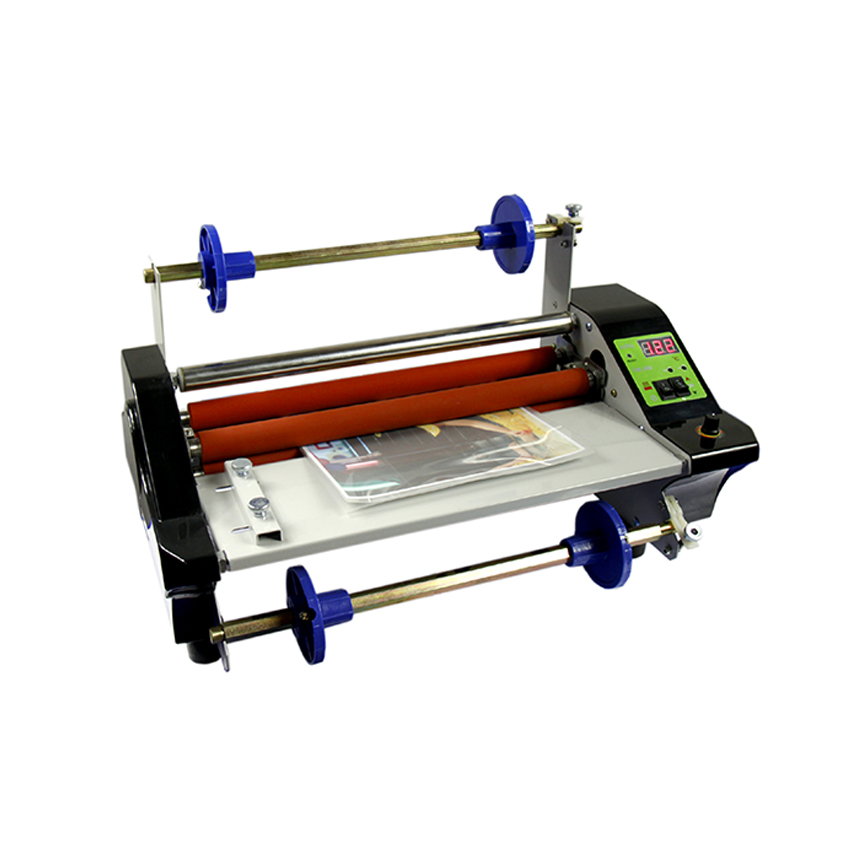

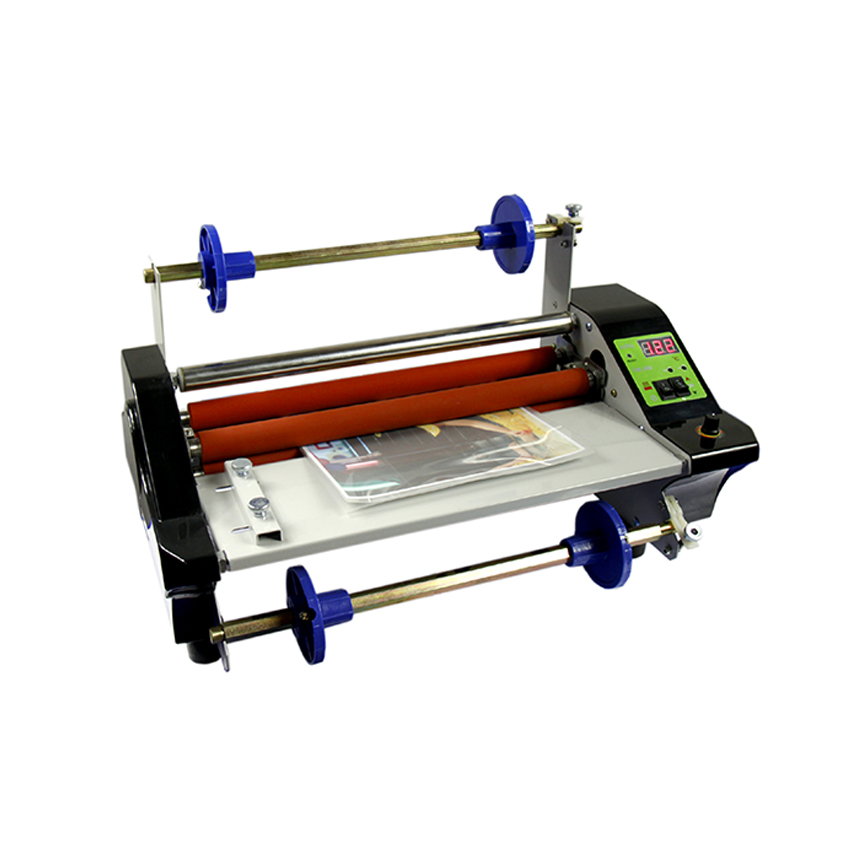

Before deploying a new industrial printer—such as a UV DTF printer, UV flatbed printer, or UV 6090 flatbed printer—into production, it is essential to conduct a complete inspection. A thorough examination guarantees your large-format printer runs smoothly, prevents needless downtime, and increases its longevity.

As a reputable provider of industrial printers, we advise you to examine your just delivered printing equipment by following our detailed advice.

1. Examine the outside condition and packaging.

Check the packing for indications of transit damage before opening the box. Take pictures right away and let the delivery company and your industrial printer supplier know if the exterior box is seriously dented or torn.

After the machine has been unpacked, check its outside for:

Dents, cracks, or scratches

Misaligned panels or loose screws

Model, serial number, and voltage requirements should all be properly labelled.

Note any physical damage you see and get in touch with the source for more details.

2. Examine every part and accessory.

There should be a packing list included with your industrial printer or UV printer. Verify everything that is included, including:

Grounding wires and power cables

Systems of ink (if separate or pre-installed)

Make sure the printheads are packed tightly.

CDs and USB sticks containing user manuals, software, and drivers

Extra nozzles, repair kits, or replacement components

Components missing?

Contact your source right away.

3. Examine the Ink and Printhead System

Your UV flatbed printer or UV DTF printer's printhead is its central component. Verify that the printhead is clear of debris and clean before turning on the computer.

Make sure there are no ink leaks.

Make sure there are no kinks in any of the ink tubes' connections.

Verify that the cartridges or ink tanks are sealed and undamaged if your printer uses pre-installed ink.

4. Turn on and perform preliminary tests.

Turn the machine on once everything appears to be in order. Take these actions:

A. Examine the software and control panel

Make that the control panel or touchscreen reacts appropriately.

Make that the included RIP software recognises the printer after installing it.

B. Examine the Nozzle

Verify that every nozzle is firing correctly by running a test print.

Do a cleaning cycle (see the handbook) if any nozzles are clogged.

C. Test Printing on Various Substances

Use a UV 6090 flatbed printer to print on a variety of surfaces, including metal, wood, and acrylic.

Verify the colour quality and alignment of a large-format printer.

Recalibrate the device or get in touch with technical assistance if the print quality is subpar.

5. Examine Safety Features and Mechanical Movements

Due to the moving parts of industrial printers, make sure the gantry moves smoothly and without making odd noises.

Ink is thoroughly cured by the UV lamp, if applicable.

Buttons for emergency stops work properly.

6. Verify Support and Warranty Information

Prior to approving the delivery:

Contact the industrial printer supplier to register your warranty.

Keep all of your paperwork, including your warranty card, invoice, and service contacts.

If necessary, enquire about installation assistance or training.

As a reputable provider of industrial printers, we advise you to examine your just delivered printing equipment by following our detailed advice.

1. Examine the outside condition and packaging.

Check the packing for indications of transit damage before opening the box. Take pictures right away and let the delivery company and your industrial printer supplier know if the exterior box is seriously dented or torn.

After the machine has been unpacked, check its outside for:

Dents, cracks, or scratches

Misaligned panels or loose screws

Model, serial number, and voltage requirements should all be properly labelled.

Note any physical damage you see and get in touch with the source for more details.

2. Examine every part and accessory.

There should be a packing list included with your industrial printer or UV printer. Verify everything that is included, including:

Grounding wires and power cables

Systems of ink (if separate or pre-installed)

Make sure the printheads are packed tightly.

CDs and USB sticks containing user manuals, software, and drivers

Extra nozzles, repair kits, or replacement components

Components missing?

Contact your source right away.

3. Examine the Ink and Printhead System

Your UV flatbed printer or UV DTF printer's printhead is its central component. Verify that the printhead is clear of debris and clean before turning on the computer.

Make sure there are no ink leaks.

Make sure there are no kinks in any of the ink tubes' connections.

Verify that the cartridges or ink tanks are sealed and undamaged if your printer uses pre-installed ink.

4. Turn on and perform preliminary tests.

Turn the machine on once everything appears to be in order. Take these actions:

A. Examine the software and control panel

Make that the control panel or touchscreen reacts appropriately.

Make that the included RIP software recognises the printer after installing it.

B. Examine the Nozzle

Verify that every nozzle is firing correctly by running a test print.

Do a cleaning cycle (see the handbook) if any nozzles are clogged.

C. Test Printing on Various Substances

Use a UV 6090 flatbed printer to print on a variety of surfaces, including metal, wood, and acrylic.

Verify the colour quality and alignment of a large-format printer.

Recalibrate the device or get in touch with technical assistance if the print quality is subpar.

5. Examine Safety Features and Mechanical Movements

Due to the moving parts of industrial printers, make sure the gantry moves smoothly and without making odd noises.

Ink is thoroughly cured by the UV lamp, if applicable.

Buttons for emergency stops work properly.

6. Verify Support and Warranty Information

Prior to approving the delivery:

Contact the industrial printer supplier to register your warranty.

Keep all of your paperwork, including your warranty card, invoice, and service contacts.

If necessary, enquire about installation assistance or training.

RECENT POSTS

-

How to Inspect Newly Delivered Industrial Printing Equipment?

-

دليل شراء الطابعات الصناعية: حلول فعّالة من حيث التكلفة لعام ٢٠٢٤

-

A Complete Guide to the Best Industrial Printer for Textile Printing

-

What Is The Difference Between UV Printers And DTF Printers?

-

ما هي إيجابيات الطابعات المسطحة بالأشعة فوق البنفسجية؟

Application

-

DTF Printer Effect ShowDirect to film printer(DTF printers) are T-shirt transfer printers,Hstar DTF printer offer a transfer solution especially for dark color fabric,which is a creative application process.

DTF Printer Effect ShowDirect to film printer(DTF printers) are T-shirt transfer printers,Hstar DTF printer offer a transfer solution especially for dark color fabric,which is a creative application process. -

Hstar printer in Turkey ExhibitionIn September, our company participated in the Turkish advertising exhibition. At the exhibition, many people are interested in our machine.

Hstar printer in Turkey ExhibitionIn September, our company participated in the Turkish advertising exhibition. At the exhibition, many people are interested in our machine.

More Application