What Is The Difference Between UV Printers And DTF Printers?

An Introduction to UV Printers

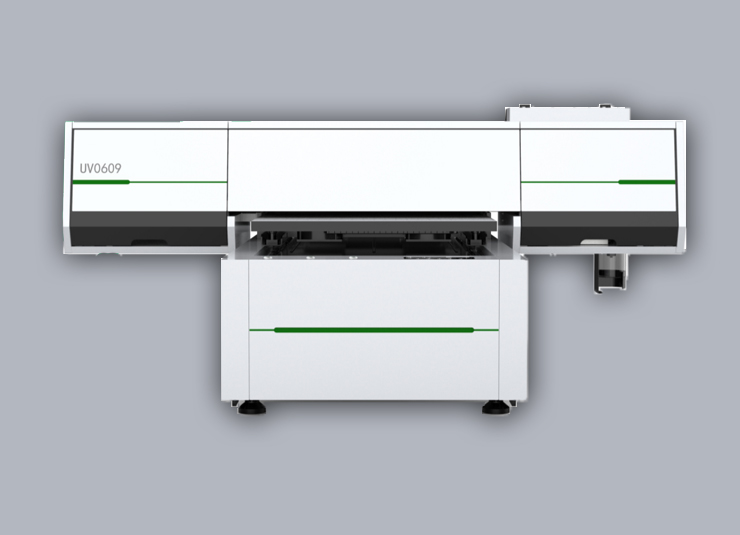

UV printers quickly cure the ink as it is applied to the substrate by using ultraviolet light. Strong ink adhesion to the substrate is ensured by UV curing, producing prints that are bright and long-lasting. The capacity of UV printers to print on a variety of materials is one of its main benefits. UV printers are capable of printing on a wide range of materials, including flexible materials like vinyl and fabric as well as solid substrates like wood, metal, and acrylic. The UV 6090 flatbed printer, for instance, is a well-liked option for companies that need flexibility in their printing processes because of its ability to work with a variety of materials.

The capability of DTF printers to produce white ink is an additional benefit. Because it enables vivid and colourful graphics, this is particularly helpful for printing on dark or coloured textiles. DTF printers are appropriate for companies with high-volume printing requirements since they can effectively manage big production runs.

4. Price

Additionally, the price of DTF and UV printers may vary. UV printers can be somewhat pricey, particularly ones with sophisticated features and capabilities. Even though they still require a substantial investment, DTF printers might be more cost-effective for certain companies, particularly those that specialize in textile printing.

Conversely, DTF printers are comparatively simpler to use. Printing on the film, applying the powder, and then using the heat press are the primary steps in the process. The procedures are simpler, and it becomes a more routine process after the printer and heat press's initial settings are adjusted for a certain kind of fabric. Because of this, DTF printers are a fantastic choice for startups or small enterprises.

In conclusion, your particular business needs will determine whether you choose a UV printer or a DTF printer. A UV printer can be the best option for you if you need a flexible printer that can create detailed, high-resolution prints on a variety of materials. A DTF printer, on the other hand, would be a better choice if you specialise in textile printing and require a device that can create brilliant, soft-hand prints on textiles. When making this crucial choice, take into account your printing needs, financial constraints, long-term company objectives, maintenance capacities, and operator skill levels.

UV printers quickly cure the ink as it is applied to the substrate by using ultraviolet light. Strong ink adhesion to the substrate is ensured by UV curing, producing prints that are bright and long-lasting. The capacity of UV printers to print on a variety of materials is one of its main benefits. UV printers are capable of printing on a wide range of materials, including flexible materials like vinyl and fabric as well as solid substrates like wood, metal, and acrylic. The UV 6090 flatbed printer, for instance, is a well-liked option for companies that need flexibility in their printing processes because of its ability to work with a variety of materials.

The Operation of DTF Printers

DTF printers use a CMYK + white ink combination to print the design onto a specialized transfer film. A powder that sticks to the wet ink is applied after the design has been printed on the film. The powder is then melted and the ink is bonded to the material by heat-pressing the film onto the clothing or other substrate. Textile printing works very well with DTF printers. They are able to create superior, delicate designs that are pleasant to the skin. Because of this, they are a popular option for the clothing sector, where creating patterns that feel and look fantastic is crucial. The capability of DTF printers to produce white ink is an additional benefit. Because it enables vivid and colourful graphics, this is particularly helpful for printing on dark or coloured textiles. DTF printers are appropriate for companies with high-volume printing requirements since they can effectively manage big production runs.

Important Distinctions

- The process of printing

- Compatibility of Materials

- Quality of Printing

4. Price

Additionally, the price of DTF and UV printers may vary. UV printers can be somewhat pricey, particularly ones with sophisticated features and capabilities. Even though they still require a substantial investment, DTF printers might be more cost-effective for certain companies, particularly those that specialize in textile printing.

- Cost of Maintenance

- Maintenance

- Operational Challenge

Conversely, DTF printers are comparatively simpler to use. Printing on the film, applying the powder, and then using the heat press are the primary steps in the process. The procedures are simpler, and it becomes a more routine process after the printer and heat press's initial settings are adjusted for a certain kind of fabric. Because of this, DTF printers are a fantastic choice for startups or small enterprises.

In conclusion, your particular business needs will determine whether you choose a UV printer or a DTF printer. A UV printer can be the best option for you if you need a flexible printer that can create detailed, high-resolution prints on a variety of materials. A DTF printer, on the other hand, would be a better choice if you specialise in textile printing and require a device that can create brilliant, soft-hand prints on textiles. When making this crucial choice, take into account your printing needs, financial constraints, long-term company objectives, maintenance capacities, and operator skill levels.

RECENT POSTS

Application

-

UV DTF Printer Client FeedbackA customer from Austria placed an order for our UV DTF printer after many inspections. This is their feedback after using it.

UV DTF Printer Client FeedbackA customer from Austria placed an order for our UV DTF printer after many inspections. This is their feedback after using it. -

Hstar printer in Turkey ExhibitionIn September, our company participated in the Turkish advertising exhibition. At the exhibition, many people are interested in our machine.

Hstar printer in Turkey ExhibitionIn September, our company participated in the Turkish advertising exhibition. At the exhibition, many people are interested in our machine.

More Application

.jpg)

.jpg)