What is the Difference Between a UV Printer and a Normal Printer?

Your particular requirements, the materials you wish to print on, and the level of quality you demand will all influence your decision between a UV printer and a standard printer. The main distinctions between these two kinds of printers will be discussed in this article, with an emphasis on UV flatbed printers, flatbed printers, and particular models such as the UV 6090 flatbed printer. You will have a good idea of which printer is best for you by the end.

For simple printing tasks, standard printers are inexpensive, user-friendly, and ideal. They are constrained, though. Only flat, thin materials like paper or cardstock can be used for printing, and the prints may not last very long, particularly if they are exposed to sunlight or water.

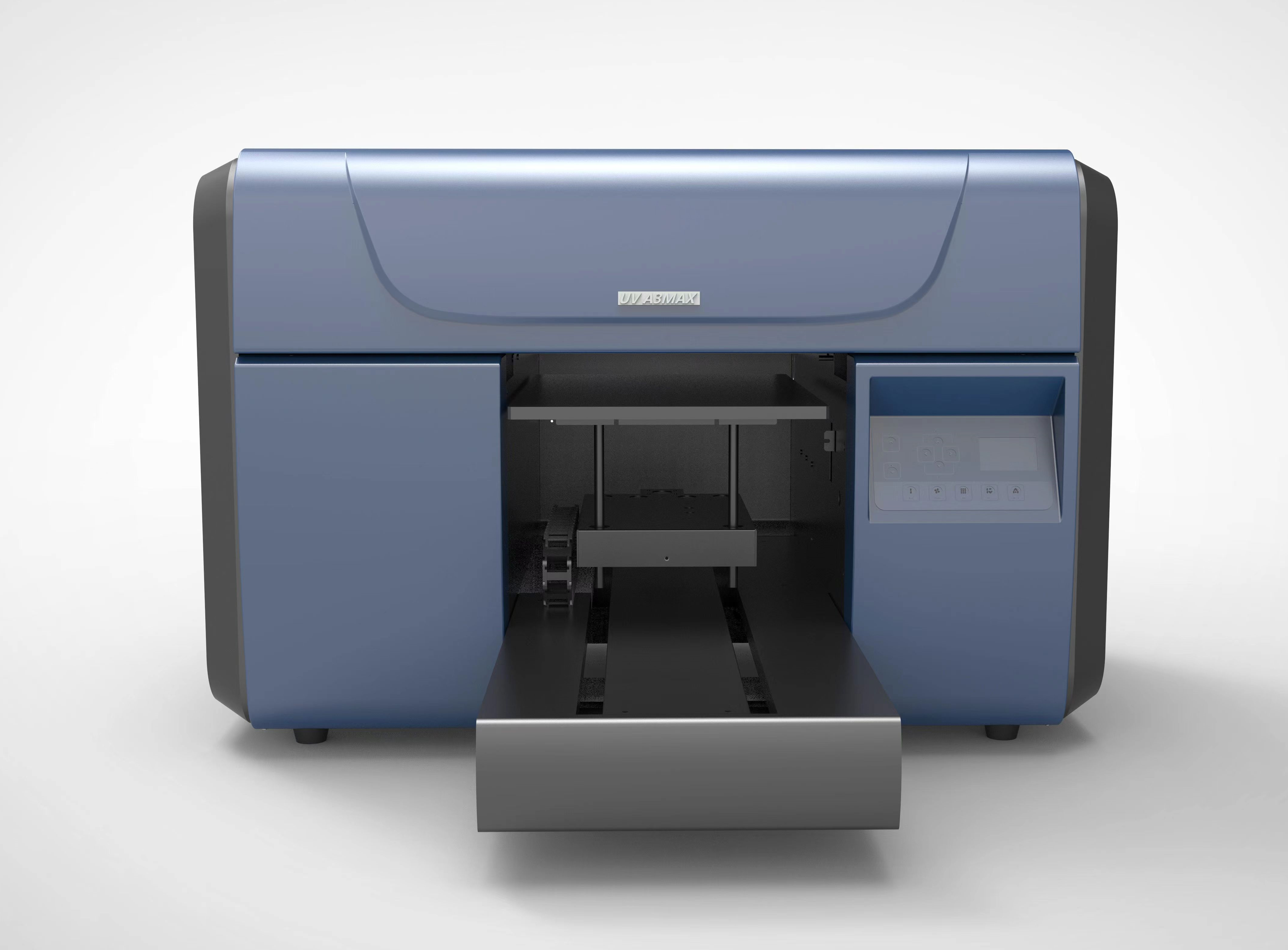

The UV flatbed printer is among the most widely used varieties of UV printers. A flatbed printer holds the material in place using a flat printing bed, unlike typical printers. It is perfect for industries like signage, packaging, and custom product decoration because of its design, which enables it to print on stiff and oddly shaped things.

UV Printers: UV-curable inks, which are instantly exposed to ultraviolet light after being deposited on the substrate, are used in UV printers. This procedure rapidly solidifies the ink, producing prints that are long-lasting and of excellent quality. Additionally, drying time is eliminated by using UV light, which speeds up and improves the efficiency of the operation.

UV Printers: Nearly any flat or slightly curved surface can be used to print on a UV printer, particularly a flatbed digital printer. This covers materials such as metal, glass, acrylic, and wood.

Normal Printers: Although normal printers are capable of producing prints of excellent quality, they are frequently only able to print on paper and may not be as long-lasting, particularly when exposed to moisture or ultraviolet light.

UV Printers: Prints from UV printers are extremely resistant to water damage, fading, and scratches. Strong adherence between the UV-cured ink and the substrate produces prints that are vivid and long-lasting. Because of this, UV printers are ideal for durable items and outdoor signage.

Custom signage, promotional materials, industrial branding, and even creative endeavours are just a few of the many uses for UV printers. A UV 6090 flatbed printer, for instance, is a well-liked option for small and medium-sized enterprises because of its modest size and versatility.

The advantages of digital printing technology and the adaptability of a flatbed design are combined in the flatbed digital printer. This eliminates the requirement for pre-treatment or post-processing and enables customers to produce high-resolution prints on a variety of substrates.

.jpg)

What is a Normal Printer?

Most people are familiar with a standard printer, like an inkjet or laser printer. For routine chores like printing documents, images, or promotional materials on paper, these printers are made. They are commonly used in homes, workplaces, and small enterprises to produce text and graphics using liquid ink or toner.For simple printing tasks, standard printers are inexpensive, user-friendly, and ideal. They are constrained, though. Only flat, thin materials like paper or cardstock can be used for printing, and the prints may not last very long, particularly if they are exposed to sunlight or water.

What is a UV Printer?

A UV printer is a more sophisticated kind of printer that instantaneously cures or dries ink as it is printed onto a surface using ultraviolet (UV) light. Glass, metal, wood, plastic, and ceramics are just a few of the materials that UV printers can now print on thanks to this technology. UV printers are extremely adaptable and appropriate for commercial, industrial, and creative applications due to their capacity to print on a wide variety of materials.The UV flatbed printer is among the most widely used varieties of UV printers. A flatbed printer holds the material in place using a flat printing bed, unlike typical printers. It is perfect for industries like signage, packaging, and custom product decoration because of its design, which enables it to print on stiff and oddly shaped things.

Key Differences Between UV Printers and Normal Printers

- Printing Technology

UV Printers: UV-curable inks, which are instantly exposed to ultraviolet light after being deposited on the substrate, are used in UV printers. This procedure rapidly solidifies the ink, producing prints that are long-lasting and of excellent quality. Additionally, drying time is eliminated by using UV light, which speeds up and improves the efficiency of the operation.

- Versatility in Materials

UV Printers: Nearly any flat or slightly curved surface can be used to print on a UV printer, particularly a flatbed digital printer. This covers materials such as metal, glass, acrylic, and wood.

- Print Quality and Durability

Normal Printers: Although normal printers are capable of producing prints of excellent quality, they are frequently only able to print on paper and may not be as long-lasting, particularly when exposed to moisture or ultraviolet light.

UV Printers: Prints from UV printers are extremely resistant to water damage, fading, and scratches. Strong adherence between the UV-cured ink and the substrate produces prints that are vivid and long-lasting. Because of this, UV printers are ideal for durable items and outdoor signage.

- Applications

Custom signage, promotional materials, industrial branding, and even creative endeavours are just a few of the many uses for UV printers. A UV 6090 flatbed printer, for instance, is a well-liked option for small and medium-sized enterprises because of its modest size and versatility.

What is a UV Flatbed Printer?

An alternative to a roll-to-roll or conveyor-based system is a UV flatbed printer, which has a flat printing bed. This architecture makes the printer extremely versatile by enabling it to handle hard and oddly shaped objects. Industries where accuracy and material adaptability are essential frequently utilize flatbed printers.The advantages of digital printing technology and the adaptability of a flatbed design are combined in the flatbed digital printer. This eliminates the requirement for pre-treatment or post-processing and enables customers to produce high-resolution prints on a variety of substrates.

The UV 6090 Flatbed Printer: A Compact Powerhouse

The UV 6090 flatbed printer is a noteworthy illustration of a UV flatbed printer. Because of its small size, this model is well-suited for companies with little space. The UV 6090 flatbed printer can handle materials up to a particular thickness and produces excellent print quality despite its modest size. It is a well-liked option for startups, small enterprises, and creative professionals in need of a dependable and adaptable printing solution..jpg)

RECENT POSTS

Application

-

UV DTF printer for Gold silver stickersGold and silver stickers that many customers like, let's see how it is made.

UV DTF printer for Gold silver stickersGold and silver stickers that many customers like, let's see how it is made. -

Application scenarios of UV DTF printersUV DTF printer is our NEW machine, which is loved by many consumers.crystal stickers are widely used.

Application scenarios of UV DTF printersUV DTF printer is our NEW machine, which is loved by many consumers.crystal stickers are widely used.

Crystal stickers can also be used as decorations to make your gift more beautiful and special.

More Application