Several common mistakes of DTF printers in T-shirt printing

Several common mistakes of DTF printers in T-shirt printing

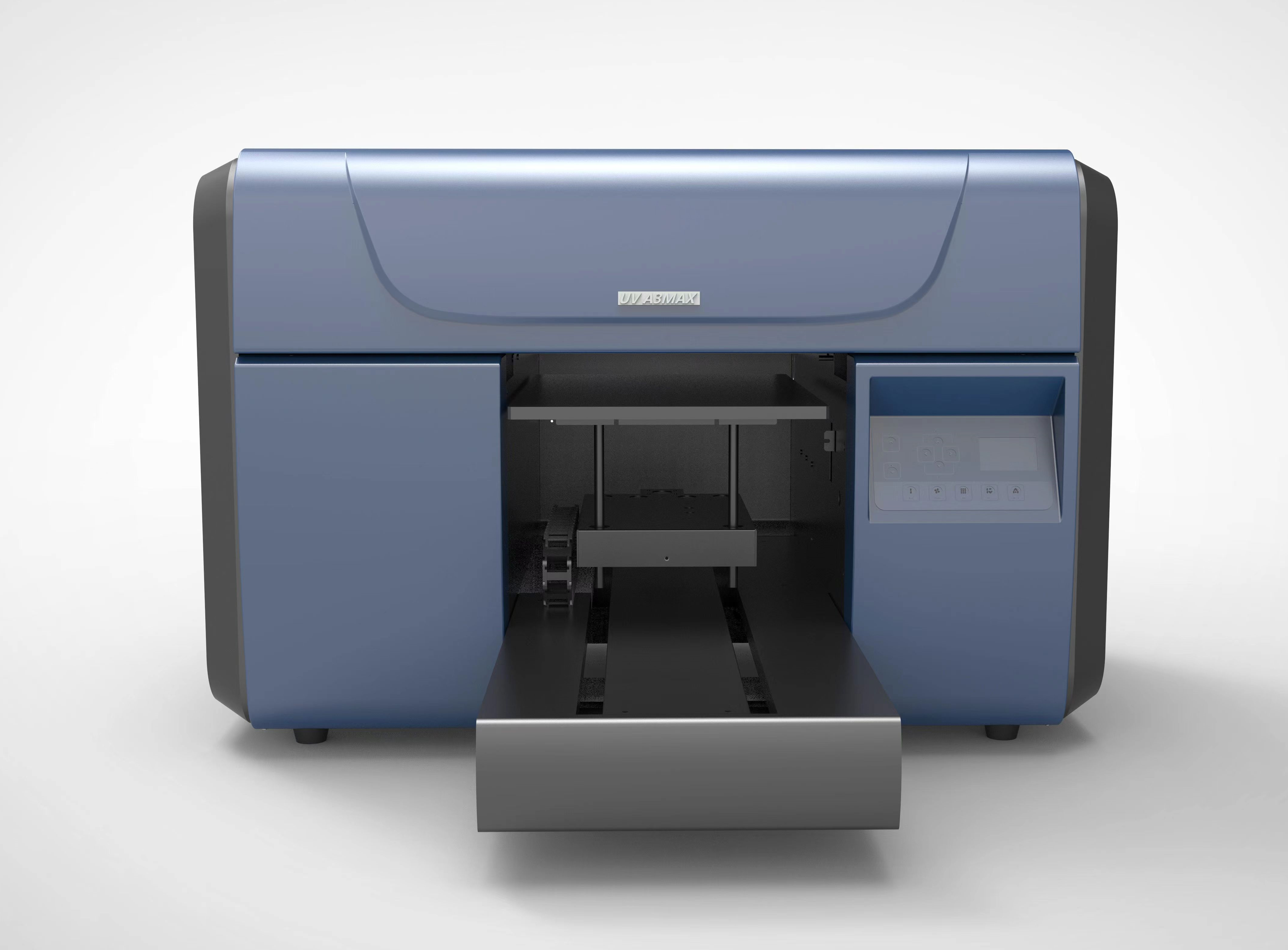

DTF (Direct-to-Film) printers are popular in T-shirt printing for their high-quality printing results and fast production efficiency. However, even advanced DTF printers may make some common mistakes during use, affecting the final printing results. This article will introduce these common mistakes and their solutions in detail to help you avoid these problems and ensure perfect printing results every time.

1. Print head clogging

Print head clogging is one of the most common problems of DTF printers, which will cause streaks or incomplete printing, thus affecting the quality of the design.

Prevention measures:

Regular maintenance is key. Make sure to clean your DTF printer every day, especially after frequent use. Take advantage of the cleaning function provided on most DTF printers.

Solution:

If you notice streaks or missing colors, run a print head cleaning cycle. If the problem persists, manually clean the print head with a lint-free cloth and cleaning solution. For severe clogging, professional service may be required.

2. Ink adhesion problems

Poor ink adhesion can cause DTF prints to peel or crack after application, affecting the durability of the print.

Prevention measures:

Make sure to use high-quality DTF printing inks and films. Low-quality materials will result in poor results.

Solution:

Check the temperature and pressure settings on your heat press. Incorrect settings can prevent the ink from properly bonding to the fabric. Adjust these settings according to the manufacturer's recommendations.

3. Film Jams

Film jams are an annoying problem that can stop your printing process or even damage your DTF machine.

Prevention:

Always use the correct type of film for your DTF printer. Make sure the film is properly loaded and that the printer rollers are clean and functioning properly.

Solution:

If a jam occurs, carefully remove the jammed film to avoid damaging the printer. Check the paper feed path for any obstructions or debris and clean it as needed.

4. Color Inconsistency

Achieving consistent color output is essential for professional-quality DTF printing. Color inconsistencies can be caused by a variety of factors, including ink quality and printer settings.

Prevention:

Calibrate your DTF printer regularly and use the appropriate ICC profile for your specific printer and ink combination.

Solution:

If color inconsistencies occur, perform a nozzle check to ensure that all colors are printing correctly. If the problem persists, adjust the color settings in your RIP software and consider switching to a higher quality ink.

5. Poor wash fastness

Poor wash fastness is a significant problem, especially for garments that are washed frequently. Prints that fade or deteriorate after washing can damage your reputation and customer satisfaction.

Prevention:

Use durable, high-quality inks and films. Use a heat press and follow the recommended curing process.

Solution:

If wash fastness issues occur, confirm that the correct temperature, pressure, and time settings are used during the heat transfer process. Make sure the fabric is properly pre-treated to improve ink adhesion.

6. Printer communication errors

Communication errors between your computer and DTF printer can interrupt your workflow and cause delays.

Prevention:

Make sure all software and firmware are up to date. Use high-quality, compatible USB or network cables.

Solution:

Restart your printer and computer. Check all cable connections and replace any faulty cables. If the problem persists, consult your printer manual or contact technical support.

7. Overheating

Overheating can damage your DTF printer and affect print quality. This problem is usually caused by long-term use or poor ventilation.

Precautions:

Make sure to place the printer in a well-ventilated area and avoid overloading it with continuous printing jobs.

Solution:

If the printer overheats, turn it off and let it cool down. Check for any obstructions to ventilation and remove dust or debris from the cooling fan.

8. Software Problems

Software failures or incompatibility may hinder your printing operations, especially if you are using outdated or unsupported software.

Precautions:

Update software and firmware regularly to ensure that the latest versions are used.

Solution:

If software problems occur, try reinstalling the printer driver and related software. If the problem persists, contact technical support.

Conclusion

DTF printing technology has many advantages in T-shirt printing, but understanding and avoiding these common mistakes is essential to ensure high-quality, durable printing results. By regular maintenance, using high-quality consumables, correctly setting device parameters, and promptly resolving technical problems, you can ensure perfect printing results every time. I hope that the introduction in this article can help you avoid these common mistakes in the DTF printing process and improve work efficiency and printing quality.

DTF (Direct-to-Film) printers are popular in T-shirt printing for their high-quality printing results and fast production efficiency. However, even advanced DTF printers may make some common mistakes during use, affecting the final printing results. This article will introduce these common mistakes and their solutions in detail to help you avoid these problems and ensure perfect printing results every time.

1. Print head clogging

Print head clogging is one of the most common problems of DTF printers, which will cause streaks or incomplete printing, thus affecting the quality of the design.

Prevention measures:

Regular maintenance is key. Make sure to clean your DTF printer every day, especially after frequent use. Take advantage of the cleaning function provided on most DTF printers.

Solution:

If you notice streaks or missing colors, run a print head cleaning cycle. If the problem persists, manually clean the print head with a lint-free cloth and cleaning solution. For severe clogging, professional service may be required.

2. Ink adhesion problems

Poor ink adhesion can cause DTF prints to peel or crack after application, affecting the durability of the print.

Prevention measures:

Make sure to use high-quality DTF printing inks and films. Low-quality materials will result in poor results.

Solution:

Check the temperature and pressure settings on your heat press. Incorrect settings can prevent the ink from properly bonding to the fabric. Adjust these settings according to the manufacturer's recommendations.

3. Film Jams

Film jams are an annoying problem that can stop your printing process or even damage your DTF machine.

Prevention:

Always use the correct type of film for your DTF printer. Make sure the film is properly loaded and that the printer rollers are clean and functioning properly.

Solution:

If a jam occurs, carefully remove the jammed film to avoid damaging the printer. Check the paper feed path for any obstructions or debris and clean it as needed.

4. Color Inconsistency

Achieving consistent color output is essential for professional-quality DTF printing. Color inconsistencies can be caused by a variety of factors, including ink quality and printer settings.

Prevention:

Calibrate your DTF printer regularly and use the appropriate ICC profile for your specific printer and ink combination.

Solution:

If color inconsistencies occur, perform a nozzle check to ensure that all colors are printing correctly. If the problem persists, adjust the color settings in your RIP software and consider switching to a higher quality ink.

5. Poor wash fastness

Poor wash fastness is a significant problem, especially for garments that are washed frequently. Prints that fade or deteriorate after washing can damage your reputation and customer satisfaction.

Prevention:

Use durable, high-quality inks and films. Use a heat press and follow the recommended curing process.

Solution:

If wash fastness issues occur, confirm that the correct temperature, pressure, and time settings are used during the heat transfer process. Make sure the fabric is properly pre-treated to improve ink adhesion.

6. Printer communication errors

Communication errors between your computer and DTF printer can interrupt your workflow and cause delays.

Prevention:

Make sure all software and firmware are up to date. Use high-quality, compatible USB or network cables.

Solution:

Restart your printer and computer. Check all cable connections and replace any faulty cables. If the problem persists, consult your printer manual or contact technical support.

7. Overheating

Overheating can damage your DTF printer and affect print quality. This problem is usually caused by long-term use or poor ventilation.

Precautions:

Make sure to place the printer in a well-ventilated area and avoid overloading it with continuous printing jobs.

Solution:

If the printer overheats, turn it off and let it cool down. Check for any obstructions to ventilation and remove dust or debris from the cooling fan.

8. Software Problems

Software failures or incompatibility may hinder your printing operations, especially if you are using outdated or unsupported software.

Precautions:

Update software and firmware regularly to ensure that the latest versions are used.

Solution:

If software problems occur, try reinstalling the printer driver and related software. If the problem persists, contact technical support.

Conclusion

DTF printing technology has many advantages in T-shirt printing, but understanding and avoiding these common mistakes is essential to ensure high-quality, durable printing results. By regular maintenance, using high-quality consumables, correctly setting device parameters, and promptly resolving technical problems, you can ensure perfect printing results every time. I hope that the introduction in this article can help you avoid these common mistakes in the DTF printing process and improve work efficiency and printing quality.

RECENT POSTS

Application

-

Hstar printer in Turkey ExhibitionIn September, our company participated in the Turkish advertising exhibition. At the exhibition, many people are interested in our machine.

Hstar printer in Turkey ExhibitionIn September, our company participated in the Turkish advertising exhibition. At the exhibition, many people are interested in our machine. -

UV DTF Printer Client FeedbackA customer from Austria placed an order for our UV DTF printer after many inspections. This is their feedback after using it.

UV DTF Printer Client FeedbackA customer from Austria placed an order for our UV DTF printer after many inspections. This is their feedback after using it.

More Application