Can I transfer white ink on films(DTF Print) with an iron?

Can I transfer white ink on films(DTF Print) with an iron?

DTF white ink hot stamping process has brought major changes to the textile decoration industry, especially in the field of clothing. With this process, it is possible to create high-quality prints with fine patterns and realistic colors, greatly enhancing the visual appeal of the product. However, with the increasing popularity of white ink hot stamping technology, some misunderstandings have also arisen.

When communicating with new customers, we often encounter such a question: "Can you use a household iron to transfer DTF white ink hot stamping patterns directly to the fabric?" In theory, this is not entirely impossible, but more importantly, we need to weigh the pros and cons: do the advantages outweigh the disadvantages, or the opposite?

While pursuing efficiency and convenience, ensuring the perfect presentation and durability of DTF white ink hot stamping printing is the core that we should pay more attention to. Next, let's delve deeper and uncover the mystery.

1.white ink hot stamping: accurate and durable art process

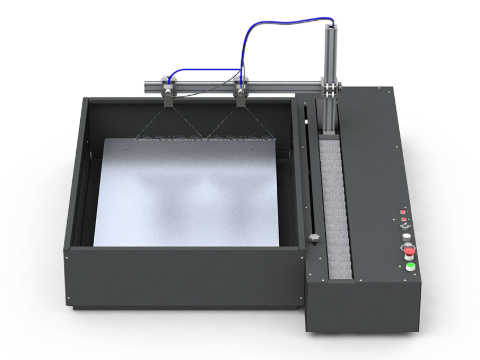

As a new and efficient printing process, DTF white ink hot stamping can realize the production of high resolution images with the help of DTF special ink, hot melt powder and PET hot stamping film. The transfer principle is to use heat and pressure to bake the hot melt powder and promote the pattern to adhere firmly to the fabric. The hot stamping produced by this process is extremely durable, and even after more than 50 washes, there will be no bleaching or falling. So, can an ordinary iron achieve such excellent durability?

2. Comprehensive Comparison between Irons and Heat Press Machines

(1) Pressure

Iron: Since its operation relies on manual control, it has limitations in precise pressure management. During the transfer process, it's very likely to cause uneven adhesion.

Heat Press Machine: Professional heat press machines, with their robust mechanical structures, can apply uniform and stable pressure across the entire transfer area. This ensures that every detail of the heat - transferred pattern adheres closely to the fabric, effectively reducing the risk of the pattern peeling or cracking.

(2) Temperature - holding Performance

Iron: The temperature adjustment of an iron is not very precise. It is easily affected by the operator's experience and environmental factors, ultimately resulting in unstable and highly variable transfer quality.

Heat Press Machine: Heat press machines are equipped with advanced temperature control systems. They can accurately adjust and maintain the optimal transfer temperature, thereby optimizing the bonding effect between the ink and the fabric and ensuring consistent transfer quality.

(3) Durability

Iron: If the ironing operation is improper, the heat - transferred pattern may fade or peel off after several washes. This not only spoils the aesthetics of the textile but also affects its wearability, greatly reducing the user experience.

Heat Press Machine: The DTF white ink heat transfer completed by a professional heat press machine has excellent durability. It can withstand dozens of washes while still maintaining the bright color and integrity of the pattern, ensuring that the finished product is both beautiful and durable.

3.Adverse Consequences of Cutting Corners

Choosing to use an iron instead of a professional heat press machine for DTF white ink heat transfer may seem to save time and cost on the surface. However, in reality, it may trigger a series of serious negative effects.

(1) Decline in Customer Satisfaction

The non - durable heat - transferred products are highly likely to dissatisfy customers, which in turn leads to negative reviews.

(2) Impairment of Profit Margins

Ultimately, due to customer returns and exchanges, more time and effort will be consumed, resulting in a reduction in profit margins.

(3) Damage to Brand Image

The brand reputation will be hit, which has an adverse impact on the long - term development and profitability of the enterprise.

Hstar has always firmly believed that excellent quality is the foundation of all successful enterprises, especially in the highly competitive textile decoration industry. We recommend that you use a professional heat press machine for DTF white ink heat transfer to ensure that the heat - transferred products can meet high standards in terms of durability, color vibrancy, and overall quality.

Although taking shortcuts may seem attractive in the pursuit of efficiency or cost - savings, the risks associated with using an iron for DTF white ink heat transfer far outweigh the potential benefits.

The DTF white ink heat transfer technology holds broad prospects and infinite possibilities. We should invest more in the right tools and work processes. This is not only a manifestation of being responsible for the brand but also a sign of respect and a solemn commitment to customers.

DTF white ink hot stamping process has brought major changes to the textile decoration industry, especially in the field of clothing. With this process, it is possible to create high-quality prints with fine patterns and realistic colors, greatly enhancing the visual appeal of the product. However, with the increasing popularity of white ink hot stamping technology, some misunderstandings have also arisen.

When communicating with new customers, we often encounter such a question: "Can you use a household iron to transfer DTF white ink hot stamping patterns directly to the fabric?" In theory, this is not entirely impossible, but more importantly, we need to weigh the pros and cons: do the advantages outweigh the disadvantages, or the opposite?

While pursuing efficiency and convenience, ensuring the perfect presentation and durability of DTF white ink hot stamping printing is the core that we should pay more attention to. Next, let's delve deeper and uncover the mystery.

1.white ink hot stamping: accurate and durable art process

As a new and efficient printing process, DTF white ink hot stamping can realize the production of high resolution images with the help of DTF special ink, hot melt powder and PET hot stamping film. The transfer principle is to use heat and pressure to bake the hot melt powder and promote the pattern to adhere firmly to the fabric. The hot stamping produced by this process is extremely durable, and even after more than 50 washes, there will be no bleaching or falling. So, can an ordinary iron achieve such excellent durability?

2. Comprehensive Comparison between Irons and Heat Press Machines

(1) Pressure

Iron: Since its operation relies on manual control, it has limitations in precise pressure management. During the transfer process, it's very likely to cause uneven adhesion.

Heat Press Machine: Professional heat press machines, with their robust mechanical structures, can apply uniform and stable pressure across the entire transfer area. This ensures that every detail of the heat - transferred pattern adheres closely to the fabric, effectively reducing the risk of the pattern peeling or cracking.

(2) Temperature - holding Performance

Iron: The temperature adjustment of an iron is not very precise. It is easily affected by the operator's experience and environmental factors, ultimately resulting in unstable and highly variable transfer quality.

Heat Press Machine: Heat press machines are equipped with advanced temperature control systems. They can accurately adjust and maintain the optimal transfer temperature, thereby optimizing the bonding effect between the ink and the fabric and ensuring consistent transfer quality.

(3) Durability

Iron: If the ironing operation is improper, the heat - transferred pattern may fade or peel off after several washes. This not only spoils the aesthetics of the textile but also affects its wearability, greatly reducing the user experience.

Heat Press Machine: The DTF white ink heat transfer completed by a professional heat press machine has excellent durability. It can withstand dozens of washes while still maintaining the bright color and integrity of the pattern, ensuring that the finished product is both beautiful and durable.

3.Adverse Consequences of Cutting Corners

Choosing to use an iron instead of a professional heat press machine for DTF white ink heat transfer may seem to save time and cost on the surface. However, in reality, it may trigger a series of serious negative effects.

(1) Decline in Customer Satisfaction

The non - durable heat - transferred products are highly likely to dissatisfy customers, which in turn leads to negative reviews.

(2) Impairment of Profit Margins

Ultimately, due to customer returns and exchanges, more time and effort will be consumed, resulting in a reduction in profit margins.

(3) Damage to Brand Image

The brand reputation will be hit, which has an adverse impact on the long - term development and profitability of the enterprise.

Hstar has always firmly believed that excellent quality is the foundation of all successful enterprises, especially in the highly competitive textile decoration industry. We recommend that you use a professional heat press machine for DTF white ink heat transfer to ensure that the heat - transferred products can meet high standards in terms of durability, color vibrancy, and overall quality.

Although taking shortcuts may seem attractive in the pursuit of efficiency or cost - savings, the risks associated with using an iron for DTF white ink heat transfer far outweigh the potential benefits.

The DTF white ink heat transfer technology holds broad prospects and infinite possibilities. We should invest more in the right tools and work processes. This is not only a manifestation of being responsible for the brand but also a sign of respect and a solemn commitment to customers.

RECENT POSTS

Application

-

Application scenarios of UV DTF printersUV DTF printer is our NEW machine, which is loved by many consumers.crystal stickers are widely used.

Application scenarios of UV DTF printersUV DTF printer is our NEW machine, which is loved by many consumers.crystal stickers are widely used.

Crystal stickers can also be used as decorations to make your gift more beautiful and special. -

Hstar printer in Turkey ExhibitionIn September, our company participated in the Turkish advertising exhibition. At the exhibition, many people are interested in our machine.

Hstar printer in Turkey ExhibitionIn September, our company participated in the Turkish advertising exhibition. At the exhibition, many people are interested in our machine.

More Application