Advantages of Vision-Positioned UV Printers

Advantages of Vision-Positioned UV Printers

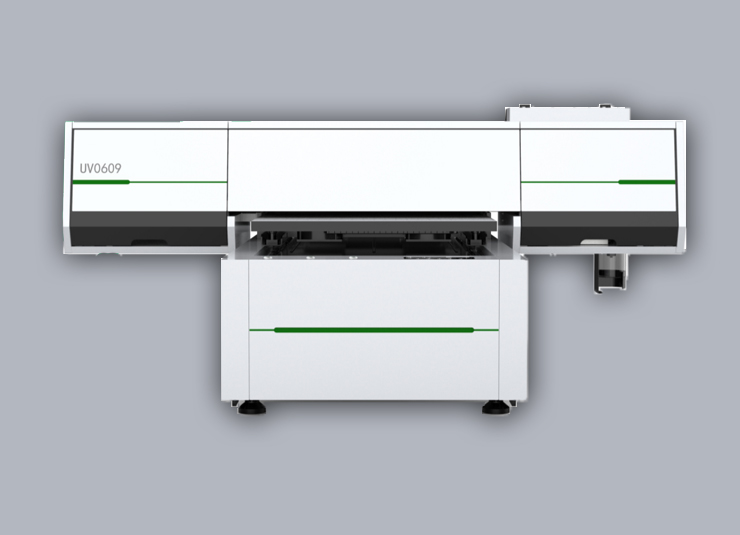

In the realm of digital printing, vision-positioned UV printers are emerging as a new favorite due to their unique technological advantages. Here are the main benefits of vision-positioned UV printers and how they can help businesses enhance production efficiency and product quality.

1. Enhanced Precision and Speed

Vision-positioned UV printers utilize advanced vision positioning systems to capture positional and shape information of the printing objects, enabling precise positioning. This high-precision positioning capability gives printers a distinct advantage when printing high-precision, high-resolution images or text. Additionally, vision-positioned UV printers typically feature efficient print heads and advanced control systems, allowing for high-speed printing and significantly improving production efficiency.

2. Increased Stability and Reliability

Vision-positioned UV printers are meticulously designed and optimized for higher stability and reliability. This means that during extended periods of operation, the printers can maintain stability and reliability, reducing malfunctions and issues, thereby enhancing production efficiency and product quality.

3. Broad Material Compatibility

Vision-positioned UV printers can perform high-quality printing on a variety of materials, such as paper, wood, metal, glass, and more. This wide range of material compatibility allows the printers to be applied across multiple industries, including advertising, packaging, printing, and decoration.

4. Energy Efficiency and Environmental Friendliness

Vision-positioned UV printers use UV-curing inks for printing, which do not produce toxic substances, making them environmentally friendly and energy-saving. This aligns with the green production philosophy of modern industry and helps businesses achieve sustainable development.

5. Personalization and Customization

With the increasing consumer demand for personalized products, vision-positioned UV printers can meet the printing needs for small batches and a variety of products, adding unique aesthetics and value to the products.

6. Improved Production Efficiency and Error Reduction

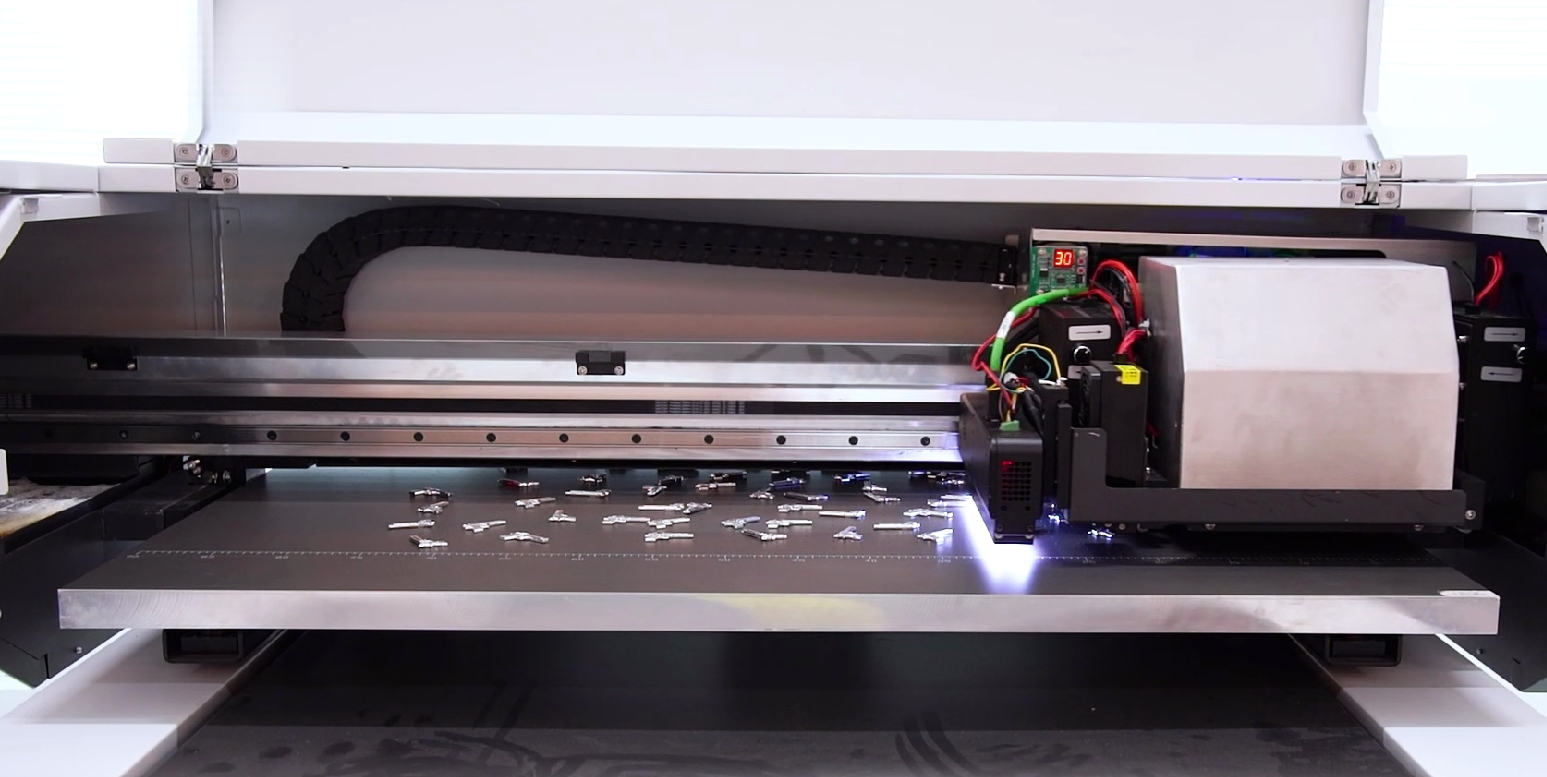

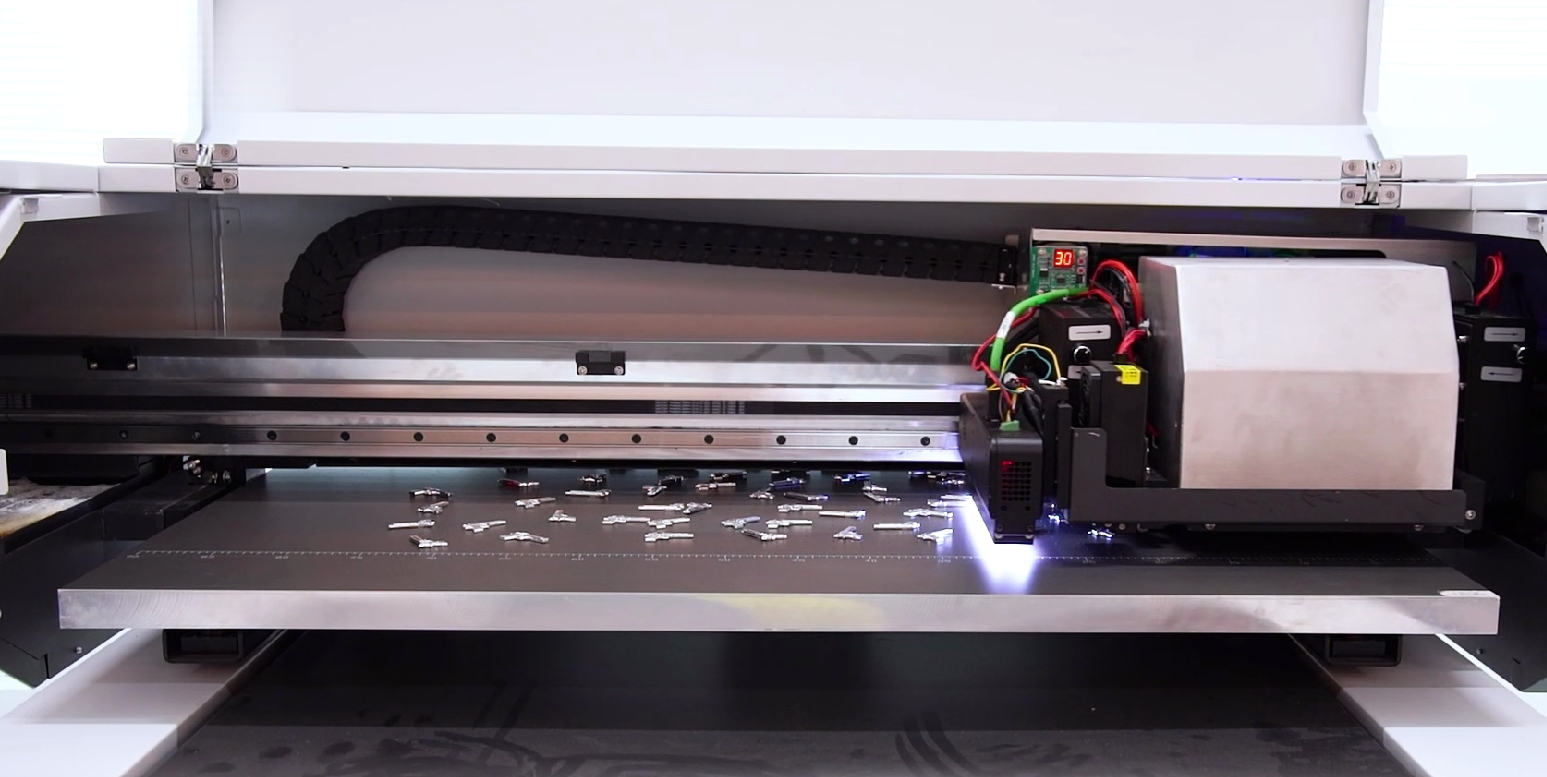

The vision positioning system can automatically recognize the position and orientation of products, reducing the time needed for manual adjustments and thus speeding up production. At the same time, precise vision recognition prevents misprints caused by human errors, ensuring that the printed content is accurately placed on the correct position of the product.

7. Enhanced Flexibility

The vision positioning feature allows UV printers to adapt to products of different shapes and sizes, increasing the flexibility and application range of the printers.

8. Support for Complex Patterns

For complex patterns that require precise alignment, vision positioning ensures that various parts of the pattern can be accurately joined during printing, avoiding misalignment.

In summary, vision-positioned UV printers, with their advantages of high precision, high speed, high stability, broad material compatibility, energy efficiency, environmental friendliness, personalization, and support for complex patterns, hold an important position in the modern printing industry. They will continue to drive the industry towards automation and intelligence.

In the realm of digital printing, vision-positioned UV printers are emerging as a new favorite due to their unique technological advantages. Here are the main benefits of vision-positioned UV printers and how they can help businesses enhance production efficiency and product quality.

1. Enhanced Precision and Speed

Vision-positioned UV printers utilize advanced vision positioning systems to capture positional and shape information of the printing objects, enabling precise positioning. This high-precision positioning capability gives printers a distinct advantage when printing high-precision, high-resolution images or text. Additionally, vision-positioned UV printers typically feature efficient print heads and advanced control systems, allowing for high-speed printing and significantly improving production efficiency.

2. Increased Stability and Reliability

Vision-positioned UV printers are meticulously designed and optimized for higher stability and reliability. This means that during extended periods of operation, the printers can maintain stability and reliability, reducing malfunctions and issues, thereby enhancing production efficiency and product quality.

3. Broad Material Compatibility

Vision-positioned UV printers can perform high-quality printing on a variety of materials, such as paper, wood, metal, glass, and more. This wide range of material compatibility allows the printers to be applied across multiple industries, including advertising, packaging, printing, and decoration.

4. Energy Efficiency and Environmental Friendliness

Vision-positioned UV printers use UV-curing inks for printing, which do not produce toxic substances, making them environmentally friendly and energy-saving. This aligns with the green production philosophy of modern industry and helps businesses achieve sustainable development.

5. Personalization and Customization

With the increasing consumer demand for personalized products, vision-positioned UV printers can meet the printing needs for small batches and a variety of products, adding unique aesthetics and value to the products.

6. Improved Production Efficiency and Error Reduction

The vision positioning system can automatically recognize the position and orientation of products, reducing the time needed for manual adjustments and thus speeding up production. At the same time, precise vision recognition prevents misprints caused by human errors, ensuring that the printed content is accurately placed on the correct position of the product.

7. Enhanced Flexibility

The vision positioning feature allows UV printers to adapt to products of different shapes and sizes, increasing the flexibility and application range of the printers.

8. Support for Complex Patterns

For complex patterns that require precise alignment, vision positioning ensures that various parts of the pattern can be accurately joined during printing, avoiding misalignment.

In summary, vision-positioned UV printers, with their advantages of high precision, high speed, high stability, broad material compatibility, energy efficiency, environmental friendliness, personalization, and support for complex patterns, hold an important position in the modern printing industry. They will continue to drive the industry towards automation and intelligence.

RECENT POSTS

Application

-

DTF Printer Effect ShowDirect to film printer(DTF printers) are T-shirt transfer printers,Hstar DTF printer offer a transfer solution especially for dark color fabric,which is a creative application process.

DTF Printer Effect ShowDirect to film printer(DTF printers) are T-shirt transfer printers,Hstar DTF printer offer a transfer solution especially for dark color fabric,which is a creative application process. -

Hstar printer in Turkey ExhibitionIn September, our company participated in the Turkish advertising exhibition. At the exhibition, many people are interested in our machine.

Hstar printer in Turkey ExhibitionIn September, our company participated in the Turkish advertising exhibition. At the exhibition, many people are interested in our machine.

More Application