Ultimate Guide to UV Printer Nozzle Maintenance and Clogging Solutions

UV Printer Nozzle Maintenance and Clogging Solutions

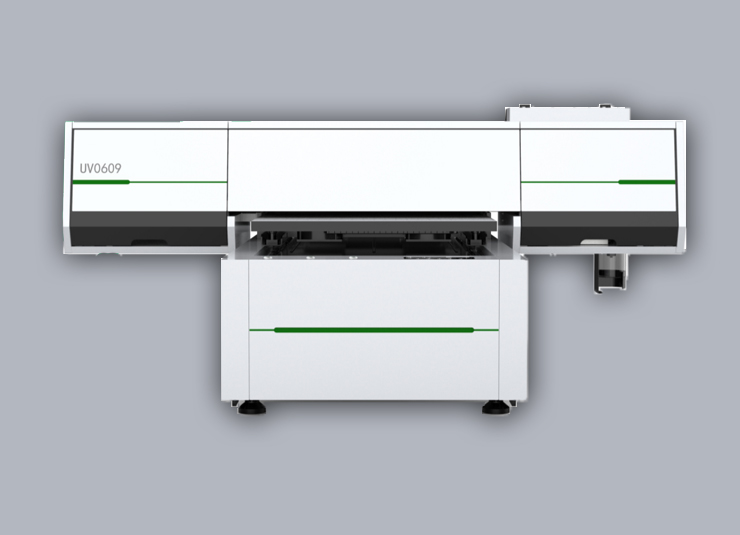

UV printers are known for their high precision and quality output, making them essential in industries such as advertising, decoration, and industrial printing. However, maintaining the nozzles is crucial for consistent print quality. This guide provides a comprehensive approach to maintaining and unclogging UV printer nozzles.

Daily Maintenance

-

Routine Cleaning: At the end of each workday, perform a routine cleaning of the nozzles. Use a special cleaning solution to wipe the nozzle surface and ensure there is no residual ink. If the print colors are uneven or unstable, clean the nozzles immediately.

-

Daily Print Test: Before starting daily operations, conduct a print test to ensure the nozzles are functioning correctly. If the colors appear darker or there are brightness differences, print the same data with the same settings and manually clean the nozzles according to usage frequency.

-

Long Holidays: During extended periods of non-use, such as holidays, remove the nozzles, clean them repeatedly with a special cleaning solution, and seal them in plastic bags.

Clogging Solutions

-

Ineffective Normal Cleaning: If normal cleaning methods fail to resolve the issue of broken lines, perform a "manual cleaning" by rinsing the nozzles with a special cleaning solution. This can be done regularly, with frequency depending on usage.

-

Deep Cleaning: If the nozzles are clogged, remove them and clean them twice with a special cleaning solution. Then, soak the nozzle surface (not the entire nozzle) in the cleaning solution for 1-2 days. After soaking, clean the nozzles once more. If the nozzles are unobstructed, they can be used. If not, continue the soaking and cleaning process.

-

Special Cleaning Solution: After soaking, inject an appropriate amount of special cleaning solution into the printer nozzles. It is imperative to use a special cleaning solution; using general cleaning solutions requires strict control over soaking time to prevent nozzle damage.

-

Temporary Non-Use: If the nozzles are not to be used temporarily, clean them with a special cleaning solution, place the treated nozzles in a clean, corrosion-resistant container, seal it, and store for about one month. If they are not used after one month, clean them again

-

DTF Printer Effect ShowDirect to film printer(DTF printers) are T-shirt transfer printers,Hstar DTF printer offer a transfer solution especially for dark color fabric,which is a creative application process.

DTF Printer Effect ShowDirect to film printer(DTF printers) are T-shirt transfer printers,Hstar DTF printer offer a transfer solution especially for dark color fabric,which is a creative application process. -

UV DTF printer for Gold silver stickersGold and silver stickers that many customers like, let's see how it is made.

UV DTF printer for Gold silver stickersGold and silver stickers that many customers like, let's see how it is made.

More Application