What is the magic of flatbed printer technology? Its fields of application are so rich!

What is the magic of flatbed printer technology?

Its fields of application are so rich!

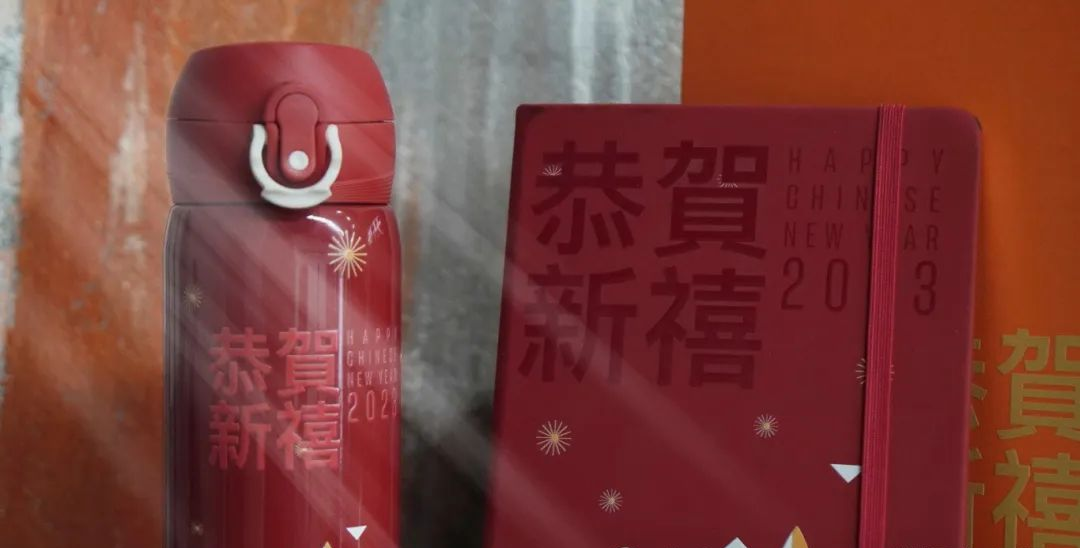

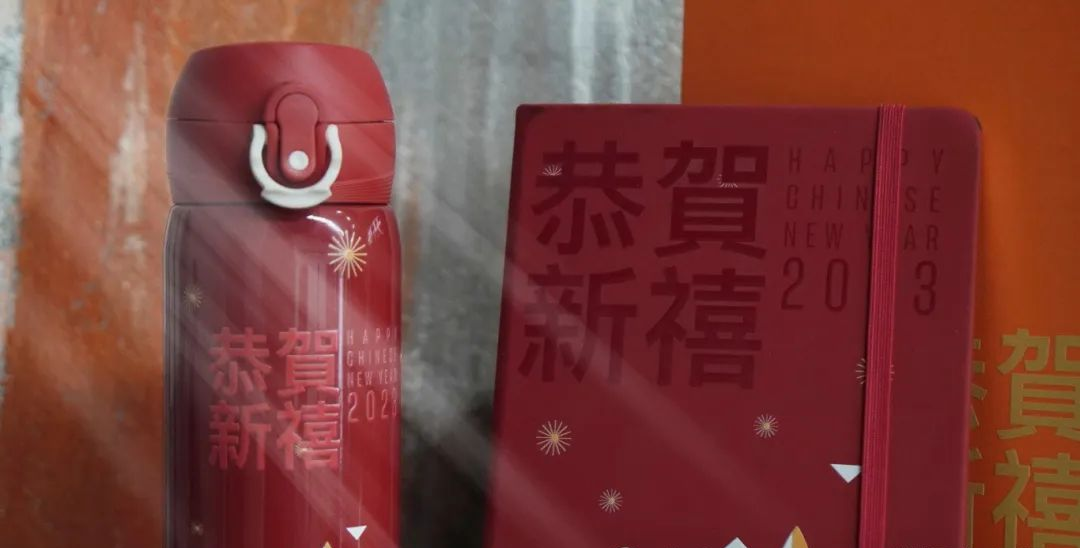

UV flatbed printers are increasingly used in all walks of life, whether in advertising, home decoration, handicraft processing, packaging, digital shells and other industries.

If you want a more three-dimensional relief effect, can UV printers achieve it? Let's find the answer together!

What is the relief effect?/01

Relief is a kind of sculpture effect that shows a sense of concavity and convexity on the surface of an object. It feels smooth and has delicate colors.

The relief effect makes the layers of the picture more distinct and the three-dimensional sense stronger. It is a unique artistic effect.

The relief effect performed by UV flatbed printers is mainly achieved by accumulating UV white ink to highlight the color range of the relief. The higher the thickness of the white ink, the more obvious the effect.

It prints patterns, shapes, and colors to give them a 3D effect visually. So how does a UV flatbed printer achieve relief?

How does a UV printer achieve embossing effects?/02

1. Edit the pattern in the drawing software, and draw separately in the area where relief printing is required.

2. In the control software, set the addition white ink function in the place where relief effect is required (generally set it 2-3 times), and after the white ink is piled on the surface of the material, the pattern is printed on the surface of the white ink with colored ink to form a relief effect.

3. Place the printing object on the printing platform, the equipment automatically positions, and starts printing.

4. After the printing is completed, remove the printed object with relief effect from the platform.

From these short printing steps, we can see that the operation of a flatbed printer is not complicated. If you are proficient in using computer software, one person can operate several printers without any pressure, saving labor MAX!

Besides, the UV flatbed printer uses a high-precision nozzle and printing control system, which can achieve high-precision 3D relief printing to meet the requirements of delicate and complex design.

It has the advantages of high efficiency, high precision, and multifunctional printing, which is of great significance for achieving mass production, reducing production costs and improving production efficiency.

Printing range of UV flatbed printer/03

If you want to do your work well, you must first sharpen your tools.

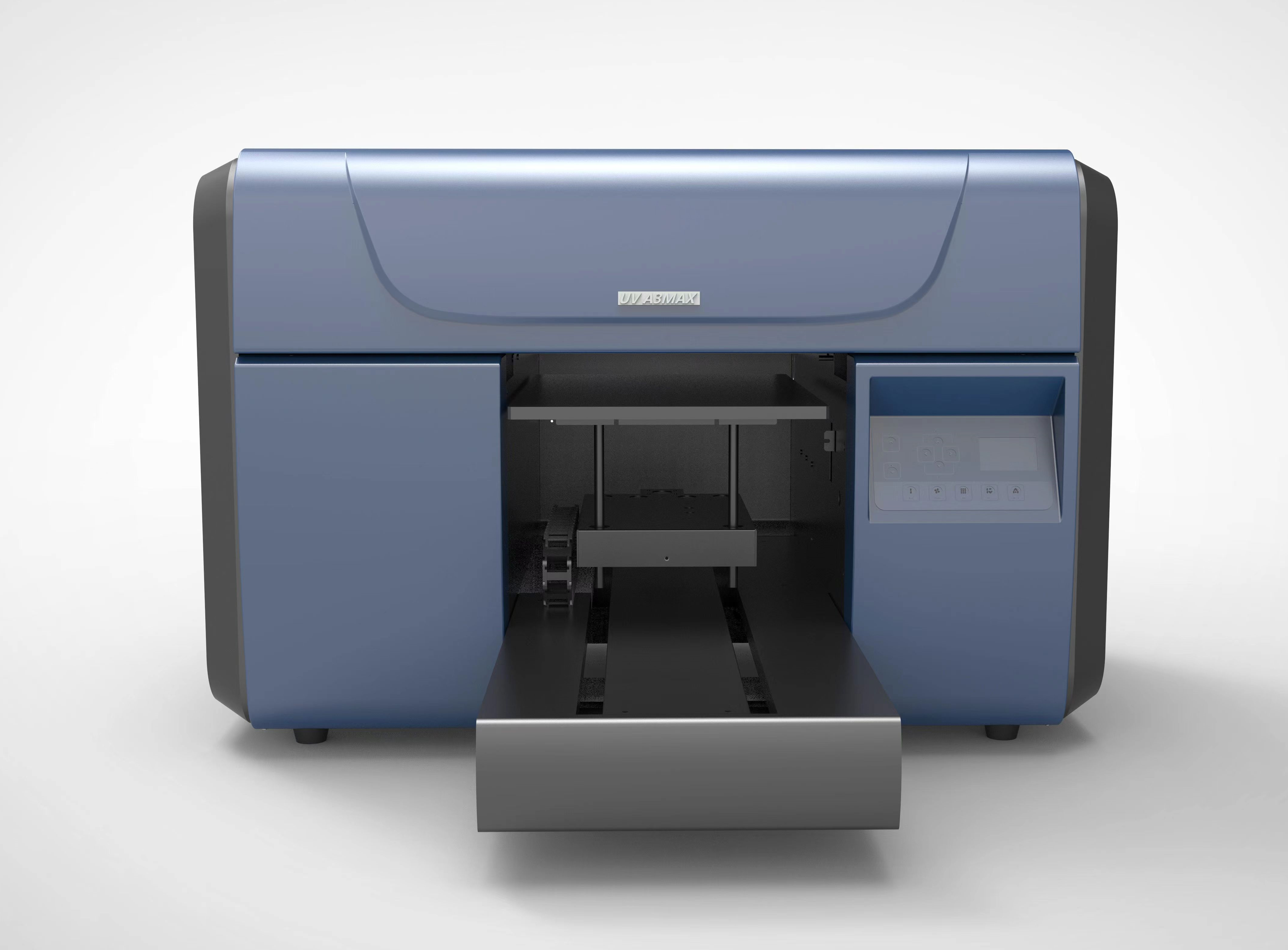

We recommend using an Hstar A3 UV MAX flatbed printer to print 3D relief products.

When drawing, add a spot color channel, and when printing relief effects, add white ink. After the white ink is printed, use color ink to print the selected pattern on the surface of the material. In this way, you can easily complete a lifelike and delicate three-dimensional relief pattern.

The relief effect printed by A3 UV MAX is not only clear in layers and has a good 3D effect, but also supports printing on a variety of materials, such as wood, acrylic, stone, glass, plastic, etc., which can all realize relief effects.

In addition, A3 UV MAX supports flat printing, roll printing, and cylinder printing, and users can choose the appropriate printing solution according to different materials.

According to the properties of the medium

Flexible medium: PVC, reflective film, oil canvas, carpet, leather, etc.

Hard medium: glass, tile, metal, ceiling, aluminum plate, wood board, door panel, acrylic plate, plexiglass board, foam board, corrugated cardboard, etc.

According to material shape

Flat materials: including tiles, glass, acrylic, wood, fiberboard, stone, plastic, KT, metal, etc.

Rolled materials: wallpaper, wall cloth, advertising cloth, spray-painted cloth, leather, carpet, soft film, etc.

Cylindrical materials: cups, tea sets, cosmetics, mice, etc.

Summary/04

Compared with traditional printers, today's UV flatbed printers have many additional advantages - low cost, fast speed, and green environmental protection. Whether it is the industry of home decoration, handicraft, office supplies or advertisement, it has the favorable position for the use of the UV flatbed.

From industrial to consumer level, from professional application to daily life, the application of UV printing technology is gradually penetrating into every corner of society. Let us wait and see!

So, what do you want to print with a UV flatbed printer? For more information about flatbed printers, please follow us!

Its fields of application are so rich!

UV flatbed printers are increasingly used in all walks of life, whether in advertising, home decoration, handicraft processing, packaging, digital shells and other industries.

If you want a more three-dimensional relief effect, can UV printers achieve it? Let's find the answer together!

What is the relief effect?/01

Relief is a kind of sculpture effect that shows a sense of concavity and convexity on the surface of an object. It feels smooth and has delicate colors.

The relief effect makes the layers of the picture more distinct and the three-dimensional sense stronger. It is a unique artistic effect.

The relief effect performed by UV flatbed printers is mainly achieved by accumulating UV white ink to highlight the color range of the relief. The higher the thickness of the white ink, the more obvious the effect.

It prints patterns, shapes, and colors to give them a 3D effect visually. So how does a UV flatbed printer achieve relief?

How does a UV printer achieve embossing effects?/02

1. Edit the pattern in the drawing software, and draw separately in the area where relief printing is required.

2. In the control software, set the addition white ink function in the place where relief effect is required (generally set it 2-3 times), and after the white ink is piled on the surface of the material, the pattern is printed on the surface of the white ink with colored ink to form a relief effect.

3. Place the printing object on the printing platform, the equipment automatically positions, and starts printing.

4. After the printing is completed, remove the printed object with relief effect from the platform.

From these short printing steps, we can see that the operation of a flatbed printer is not complicated. If you are proficient in using computer software, one person can operate several printers without any pressure, saving labor MAX!

Besides, the UV flatbed printer uses a high-precision nozzle and printing control system, which can achieve high-precision 3D relief printing to meet the requirements of delicate and complex design.

It has the advantages of high efficiency, high precision, and multifunctional printing, which is of great significance for achieving mass production, reducing production costs and improving production efficiency.

Printing range of UV flatbed printer/03

If you want to do your work well, you must first sharpen your tools.

We recommend using an Hstar A3 UV MAX flatbed printer to print 3D relief products.

When drawing, add a spot color channel, and when printing relief effects, add white ink. After the white ink is printed, use color ink to print the selected pattern on the surface of the material. In this way, you can easily complete a lifelike and delicate three-dimensional relief pattern.

The relief effect printed by A3 UV MAX is not only clear in layers and has a good 3D effect, but also supports printing on a variety of materials, such as wood, acrylic, stone, glass, plastic, etc., which can all realize relief effects.

In addition, A3 UV MAX supports flat printing, roll printing, and cylinder printing, and users can choose the appropriate printing solution according to different materials.

According to the properties of the medium

Flexible medium: PVC, reflective film, oil canvas, carpet, leather, etc.

Hard medium: glass, tile, metal, ceiling, aluminum plate, wood board, door panel, acrylic plate, plexiglass board, foam board, corrugated cardboard, etc.

According to material shape

Flat materials: including tiles, glass, acrylic, wood, fiberboard, stone, plastic, KT, metal, etc.

Rolled materials: wallpaper, wall cloth, advertising cloth, spray-painted cloth, leather, carpet, soft film, etc.

Cylindrical materials: cups, tea sets, cosmetics, mice, etc.

Summary/04

Compared with traditional printers, today's UV flatbed printers have many additional advantages - low cost, fast speed, and green environmental protection. Whether it is the industry of home decoration, handicraft, office supplies or advertisement, it has the favorable position for the use of the UV flatbed.

From industrial to consumer level, from professional application to daily life, the application of UV printing technology is gradually penetrating into every corner of society. Let us wait and see!

So, what do you want to print with a UV flatbed printer? For more information about flatbed printers, please follow us!

RECENT POSTS

Application

-

DTF Printer Effect ShowDirect to film printer(DTF printers) are T-shirt transfer printers,Hstar DTF printer offer a transfer solution especially for dark color fabric,which is a creative application process.

DTF Printer Effect ShowDirect to film printer(DTF printers) are T-shirt transfer printers,Hstar DTF printer offer a transfer solution especially for dark color fabric,which is a creative application process. -

Vango DTF printerOur DTF printer adopts an all-in-one printing design, which is more space-saving and easier to operate.This is our printing show.

Vango DTF printerOur DTF printer adopts an all-in-one printing design, which is more space-saving and easier to operate.This is our printing show.

Wide applications,design for textile printing,Suitable for all kinds of fabrics, T-shirts,leather, bags and shoes etc.

More Application

.jpg)