Important procedures and steps in the printing process - Digital printing dedicated RIP software: Raster Image Processor.

Important procedures and steps in the printing process - Digital printing dedicated RIP software: Raster Image Processor.

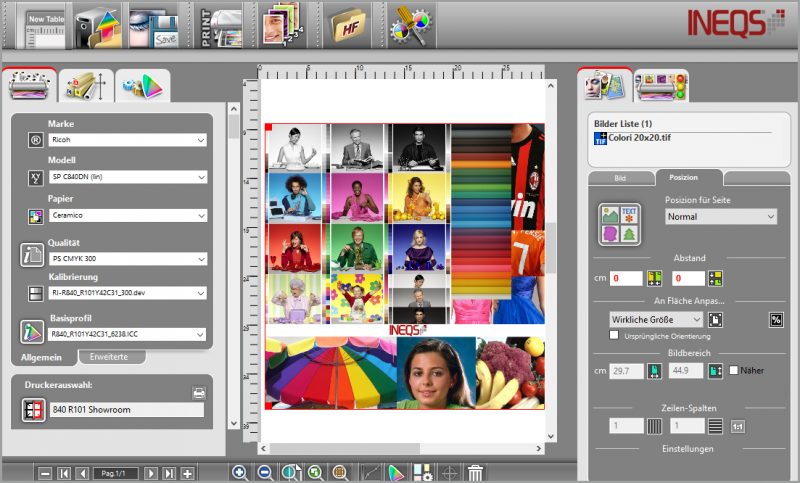

RIP (Raster Image Processor) software, namely the raster image processor, is a key software for pre-processing in the early stage of digital image output. It converts various image file formats (such as JPEG, TIFF, PSD, etc.) into dot matrix information that printers can recognize, thereby controlling printers to output images.

Its importance is reflected in the following: For industries that require high-quality printing output, such as photography, graphic design, printing, etc., RIP software is an indispensable tool. It can optimize image quality, color accuracy and resolution, and ensure that the printed finished products meet professional requirements.

The functions of RIP software in printing are as follows:

(一)Image conversion and optimization:

1.Format conversion: Interpret and convert image files generated by design software from their original formats into raster image formats that printers can accept. For example, for vector graphic files created in Adobe Illustrator by designers, RIP software will convert them into images composed of pixels for printing.

2.Image optimization: Adjust and optimize the resolution, clarity, contrast, etc. of images. For instance, for images with low resolution, RIP software can improve their resolution through interpolation algorithms to make the printing effect clearer. For images with insufficient contrast, it can enhance the contrast to make the image layers more distinct.

(二)Color management::

1.Color correction:

Different devices and file formats may have differences in color definition and expression. RIP software can correct the colors of images according to the characteristics of printers and the needs of users. For example, when converting an image in RGB color mode to CMYK color mode, RIP software will adjust the color values to ensure that the printed color is as consistent as possible with the original designed color.

2.Spot color processing:

Support spot color printing. For some designs that require special color effects, such as the specific color of a corporate logo or metallic colors, RIP software can accurately control the printer to use spot color inks for printing to ensure the accuracy and uniqueness of colors.

3.Screening processing:

In the printing field, screening is the process of converting a continuous-tone image into a halftone image by generating dots to simulate different colors and gray levels of an image. RIP software uses different screening algorithms, which affect the quality and visual effect of printed matter. Fine screening algorithms can make the dot distribution more uniform and the image transition more natural, but they may have a large calculation amount and affect the processing speed.

(三) Layout and output control:

1.Layout function: Multiple images or pages can be arranged reasonably on a single sheet of paper for printing, improving paper utilization and reducing waste. For example, when printing promotional posters, multiple different picture elements can be combined and printed on a large-format sheet of paper.

2.Output control:

It can control the printing parameters of the printer, such as printing speed, ink consumption, and printing resolution. Users can select appropriate parameter settings according to the needs of printing tasks and the performance of the printer to achieve the best printing effect. At the same time, RIP software can also support subsequent processing functions such as automatic cutting and binding of printers to improve work efficiency.

The following are the general operation steps of RIP software (there may be some differences for different software):

(一) Installation and setup:

1. Software installation:

Obtain the installation package of RIP software from official channels and install the software according to the prompts of the installation wizard. During the installation process, license information or activation codes may need to be entered.

2. Printer connection:

Connect the printer correctly to the computer and set the connection parameters of the printer in the RIP software, such as printer model, connection port, etc. For network printers, the correct IP address needs to be set.

Color management settings: According to the characteristics of the printer and the type of ink used, select an appropriate color management profile (ICC profile). If there is no suitable profile, a custom profile can be created by calibrating the printer or using professional color measurement tools.

(二)File import and processing:

1. File import: Open the RIP software and import the image files that need to be printed into the software. The supported file formats usually include common image formats such as JPEG, TIFF, PDF, etc.

2. Image adjustment: Make necessary adjustments to the imported image, such as color correction, resolution adjustment, image cropping, etc. These operations can be completed by using the tools and functions provided by the RIP software.

3. Layout: If multiple images need to be printed or page layout is required, use the layout function of the RIP software to place the images in appropriate positions and set the page size, margins and other parameters.

(三)Print preview and output:

1. Print preview: Before formal printing, conduct print preview to check whether the layout, color, content, etc. of the image are correct. The preview function can help users find potential problems and avoid errors and unnecessary waste.

2. Print output: After confirming that there are no errors, select the printer and printing parameters such as the number of copies, printing quality, paper type, etc., and then click the print button to start printing output.

Finally, here are some common RIP software: Flexi Print, Maintop, Photoprint (PP), Ultraprint by Hansen, Onyx, EFI, Wasatch, Acrorip, Neostampa, Epson Edge Print PRO, etc.

RECENT POSTS

Application

-

DTF Printer Effect ShowDirect to film printer(DTF printers) are T-shirt transfer printers,Hstar DTF printer offer a transfer solution especially for dark color fabric,which is a creative application process.

DTF Printer Effect ShowDirect to film printer(DTF printers) are T-shirt transfer printers,Hstar DTF printer offer a transfer solution especially for dark color fabric,which is a creative application process. -

UV DTF Printer Client FeedbackA customer from Austria placed an order for our UV DTF printer after many inspections. This is their feedback after using it.

UV DTF Printer Client FeedbackA customer from Austria placed an order for our UV DTF printer after many inspections. This is their feedback after using it.

More Application